Belt creep occurs in a belt-drive transmission when the drive such as a pulley, moves slightly faster than the belt. In this article, you will learn the definition of belt creep, its cause, belt creep vs belt slip, and how to reduce creep in a belt drive.

What is Belt Creep?

Belt creep refers to the uneven extensions and contractions of a belt when it passes from the tight side of its drive to the slack side. As a result, there is a relative motion between the belt and its drive surface. Consequently, there will be a slight reduction in the speed of the driven pulley or follower. Thus, the ratio of the speed of the driven pulley (N2), to the speed of the driver pulley (N1), is now a function of more factors. First is Young’s modulus of the belt material (E), then the respective pulley diameters (d1 and d2), and the stress in the belt on the tight and slack sides (σ1 and σ2).

![]()

Cause of Belt Creep

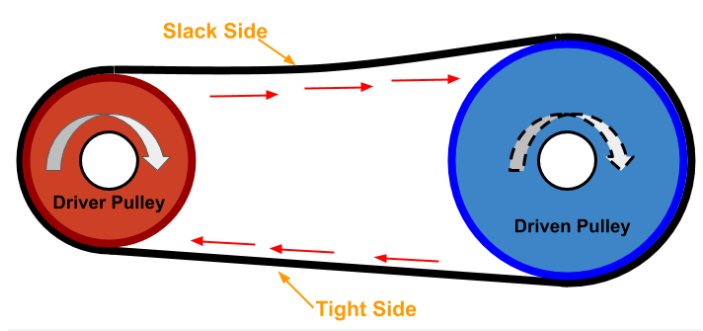

Simply put, the cause of belt creep is when the tension is uneven across both sides of a belt drive. Consider an open belt drive rotating in the clockwise direction, as the diagram below highlights.

The section of the belt moving towards the driver pulley (tight side) experiences more tension than the section moving away from the driver pulley (slack side). So, as the belt rotates, it expands on the tight side and contracts on the slack side. Due to this, relative motion of the belt occurs over the pulleys. Furthermore, even in systems where the design ensures equal tension in the belt drive, creeping is still possible. This occurs due to belt wear over time as a result of material defects and quality. Thus, one side of the drive provides more traction than the other, resulting in creep.

Creep vs Slip

The concepts of belt creep and slip are often misinterpreted as the same phenomenon. Although they have the same effect by both reducing the velocity ratio of pulleys in a transmission system, they are inherently different. Slip (s), expresses as a percentage, in a transmission system is as follows:

![]()

If the thickness of the belt (t), is brought into consideration, an expression of the slip is given as:

![]()

Clearly, as the formula above shows, both slip and creep lead to the reduction in the velocity ratio of a drive. Nevertheless, the concepts of slip and creep are quite different as the table below highlights.

| Creep | Slip |

| Creep is due to the elastic property of the belt material. | Slip occurs because of insufficient frictional grip between the pulley and belt. |

| The immediate effect of creep is the reduction of the velocity of the driven pulley, then ultimately, the velocity ratio of the transmission system. | The immediate effect of slip is a reduction in the velocity ratio of the transmission system. |

| Because the occurrence of creep relates to the belt material property, it is a function of the load, temperature, and the amount of time the drive operates. | Slip is solely a function of friction between the belt and pulley. |

| Theoretically, creep cannot be calculated, but its impact on the speed ratio of the pulleys can be calculated using the belt’s Young’s modulus, stress in the slack and tight side, and the diameters of the pulley. | Theoretically, slip can be calculated as it relates to the rotational speed of the pulleys and their diameter. |

How to Reduce Belt Creep

Because the occurrence of belt creep relates to the belt material, the ways of reducing it include:

- Proper selection of belt material: Whatever belt material an engineer chooses for an application should fit its working conditions. The operation time of the drive, the temperature range of the working environment, and the loading incurred shall be considered when selecting a belt material.

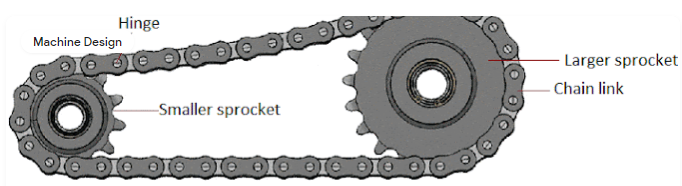

- Chain drives: These consist of rigid links with intermittent recesses to fit in with teeth projections of its wheels (sprockets). As a result, the chain and wheels move together without any creep because of the constraint. Using chain drives is a common way of avoiding creep, but it comes at a higher cost than belt drives. In addition, its design and installation require higher levels of technical competence.