A golden weld, or closure weld, is simply a welded joint that does not undergo pressure tests. Such welds go through extensive non-destructive testing (NDT) to ensure they are defect-free in line with standards. This article gives an overview of golden weld applications, their code applicability, methods of validating the weld suitability, and measures to take when executing welds.

Applications

Pressure testing is a prerequisite to putting welded joints into service. However, an exemption from the test is possible if it is not technically feasible. Thus, the use of golden welds on such joints. In practice, these joints occur often in the following applications.

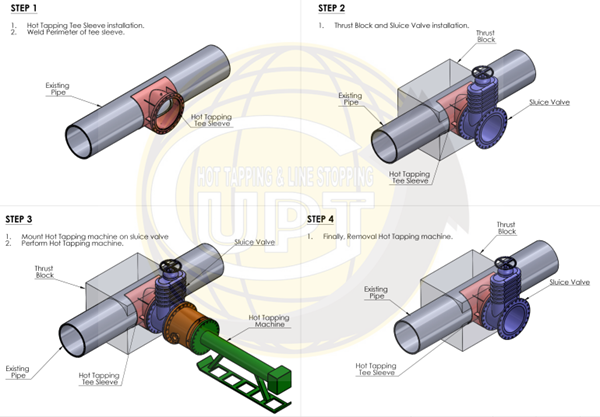

Hot Tapping

Hot tapping, or pressure tapping, is the method of making a connection to an existing pressure vessel, process system, or pipeline without putting it out of service. This ensures the continuous operation of the existing infrastructure and minimizes production downtime. Predominantly, welders use golden welds in securing the hot tap joint because it is not possible to pressure test it while the existing pipeline remains in operation.

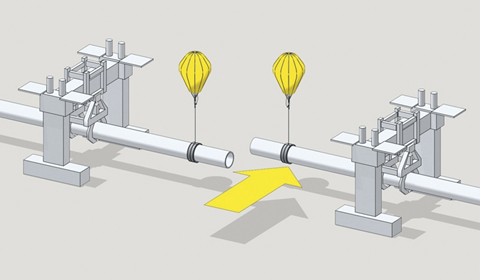

Tie-ins

In large pipeline networks, it is common to fabricate and install different sections separately. For instance, a pipeline takes products from a subsea well. This pipeline passes through an offshore processing facility, and finally to an onshore refinery. Thus, the setup has multiple major sections. Frequently, different companies handle the fabrication and installation of each section to reduce the project timeframe. As a result, the common method of joining these pipe sections is by using golden welds.

Code Applicability

The absence of pressure tests makes the use of golden welds a delicate procedure. In any case, various codes have made recommendations on how best to deploy them.

ASME B31

The ASME code for pressure piping, B31, provides guidance for the use of golden welds. These guidelines are in sections B31.3 (Process Piping), and B31.4 (Pipeline Transportation System for Liquids and Slurries). The code permits the use of golden welds for tie-ins because it is often necessary to divide pipelines into test sections and install them separately.

However, the condition for using this type of weld is extensive NDT. According to the code, the NDT shall consist of a visual inspection, supplemented by at least one other method. The most common are radiographic and ultrasonic non-destructive methods. Essentially, the method should accurately interpret and quantify potential defects. This helps ensure that weld discontinuities meet acceptance standards in API 1104. The recommendation is that the weld should pass 100% radiographic examination or 100% ultrasonic examination per standard.

API RP 14-E

This code recommends the use of golden welds if hydrostatic or pneumatic tests will have an adverse effect on the piping or operating fluid.

API 1104

This code entails recommended practices for welding pipelines and related facilities. It also encompasses qualification requirements for welders. The company is to choose welders who have the highest level of qualification available with the least error rate from previous jobs when making golden welds. In addition, the code includes acceptance criteria for the non-destructive inspection methods used in investigating the quality of welds.

Methods of Validating Weld Suitability

ASME B31.3 recommends the use of ultrasonic or radiographic methods in combination with a visual inspection. However, some companies utilize magnetic particle and liquid penetrant testing in line with their specifications.

Visual Examination

This is the direct or remote observation of internal and external components of the weld joint that are accessible. The aim of this inspection is to verify dimensions, joint preparation, alignment, and other parameters by viewing. ASME BPVC, Section 5, Article 9 provides further guidance on how to execute this.

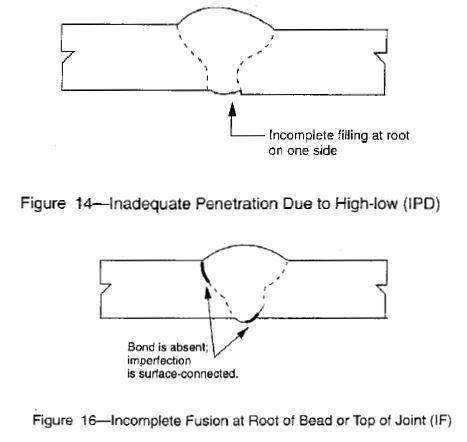

Radiographic Testing

The acceptable extent is 100% radiography as per ASME B31.3. The type of defects detected via this method includes inadequate penetration, incomplete fusion, and a host of others contained in API 1104. The acceptance criteria for each defect type are in Section 9.3 of this API standard.

Ultrasonic Testing

Ultrasonic testing produces linear, transverse, and volumetric indications. These indications are classified as defects if they exceed certain thresholds. Section 9.6.2 in API 1104 outlines the thresholds for each type of indication.

Magnetic Particle Testing

According to API 1104, relevant indications in the golden weld from this method are those that exceed 1.6 mm. Such indications require further investigation, and the acceptance criteria are in Section 9.4.2.

Liquid Penetrant Testing

Scratches, machining marks, and surface conditions on a golden weld could produce indications during this test. These are not imperfections in the weld so can be ignored. The acceptance standards for this test are in Section 9.5.2 of API 1104.

Golden Weld Procedure

Measures utilized in practice when making a golden weld vary by company in line with their requirements. A typical process is as follows:

- A qualified inspector (preferably minimum CSWIP 3.1 or AWS-CWI) should be present at all stages of welding for visual inspection.

- Leave the final length of the root bead open (about 100 mm), to aid visual inspection with a pen light. This makes it easier to identify defects such as lack of root fusion.

- Use controlled sequential welding to lessen stress in the weld.

- Take temperature measurements after each weld pass. This will ensure the interpass temperature is in line with welding procedure tolerances.

- The inspector should ensure proper cleaning and slag removal between passes.

- Carry out magnetic particle inspection (Dry Powder Technique) after root pass and hot pass.

- Do extensive NDT both prior and after Post Weld Heat Treatment (PWHT) after golden weld is complete.