A hex nut or hexagonal nut is a metal fastener with six sides. Because it appears to be the most exact shape to hold, this is one of the most popular nuts, and it can use with anchors, bolts, screws, studs, threaded rods, and any other fastener with machine screw threads.

This article will learn how a hex nut functions, sizing, markings, and grades.

How a Hex Nut Works

Hex nuts are the most versatile and commonly used nut design. In conjunction with washers and bolts, it connects both metal and wood components to prevent movement. The hex nut design allows for maximum torque and grip in a threaded fastener arrangement. Furthermore, the long length of each side allows for a more extensive surface area and high leverage at the nut when applying torque.

Because six sides give a good granularity of angles for a tool to engage, they are less prone to wear-off than their 12 point cousins. The side of the hexagon is only one-sixth of a rotation away, and provides ideal grip. Polygons with more than six sides, on the other hand, do not provide the required grip, and polygons with fewer than six sides take longer to rotate completely. These highly versatile nuts always require a wrench for installation.

Hexagonal nuts fasten a bolt or screw securely through a threaded hole. It loosened in a right-hand thread. This nut provides a secure fastening and relies on the torque to generate an axial force.

This axial force causes sufficient friction at the threads to prevent the nut from unscrewing. The power may act between the bolt head and the nut, causing compression of the parts fastened. Alternatively, it may work between adjacent nuts, allowing parts to be attached more loosely.

Sizing

The nominal thread diameter of a hex nut provides the key size. Sizes typically range from 1/4″ to 2 1/2″. Specifying size requires fractional inches rather than numerical. Hexagonal nut dimensions also define in metric sizes. Thread profiles are unified national coarse pitch (UNC), fine pitch (UNF), fixed pitch (UN), and ISO measured thread profile, depending on the application. The UNC tends to provide the standard pitch, as fine pitch (UNF) threads see use in precision applications.

Metric sizes range from M10 to M100 while Imperial measures ⅜ inch to 8 inches.

Markings

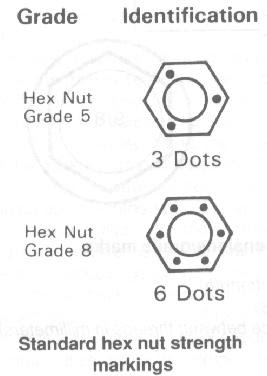

Markings on hex nut should use an indentation on the side of the bearing surface or embossment on the chamfer of the hex nut for identification. Embossed markings must not extend beyond the nut’s bearing surface.

As bolt strengths requirements increase, grades do as well. Radial lines indicate the grade or strength class of English bolts on the head. The actual grade is two lines fewer than the number of lines on the bolt head. A grade 5 bolt, for example, only possesses three radial lines on its head.

Hex Nut Grades

ASTM A563-A hex nuts are compatible with low carbon steel bolts like ASTM A307, ASTM F1554 grade 36, SAE grade 2, and AASHTO M183. SAE grade 5 and grade 8 nuts are also available in a completed pattern.

According to the nominal thickness, hex nuts classify as I type, II type, or thin type. Type I and type II nuts have a class of 8 or higher.

The type I hex nut is the most common, and it comes in three grades: A, B, and C. Machines, equipment, and structures with minor surface roughness and high precision requirements can use the A and B nuts. Type B Hex nut nuts are thicker and typically used where mounting and dismounting are frequent. C-class nuts are used on machines, equipment, or buildings with rough surfaces that do not require high precision.

Hex nuts come in various strength “grades,” as defined by the SAE (Society of Automotive Engineers). Grade 2 is the weakest in terms of power and cost; Grade 5 is a medium-strength grade, and Grade 8 is the most substantial SAE grade and the most expensive. Engineers should never substitute a lesser grade or lower strength hex nut for a graded hex nut. Surface marks identify the grade.

Materials

Steel, stainless steel, brass, silicon bronze, aluminum, and nylon are standard materials. Steel, followed by stainless steel, is the least expensive material. Copper alloys such as brass and silicon bronze are the most costly. In very rare cases, process conditions may require the use of exotic materials such as titanium or super duplex steel.

Zinc coating and hot-dip galvanizing are common steel treatments. Zinc plating, the most common and least priced commercial plating, has a moderate level of corrosion resistance. A strong zinc coating protects against corrosion in difficult situations when hot-dip galvanized.

When corrosion is a concern, 316 stainless steel is preferable over the frequently specified 304 stainless steel material. 316 stainless provides adequate protection for most applications in a salt-laden environment, although submerged applications may require additional protection.

When evaluating coating and finishing applications, engineers should be aware that compatibility issues between plating and nut material frequently exist.