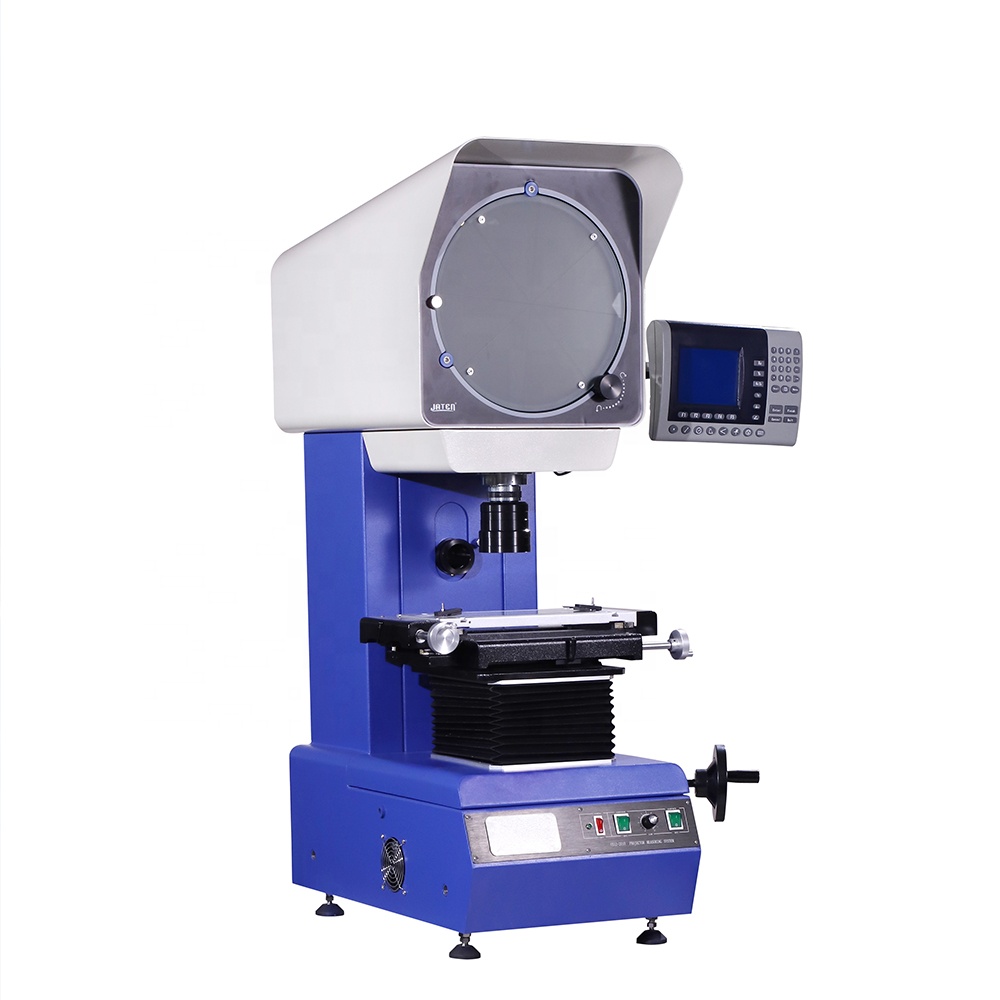

One of the best instruments to check and measure the dimensions of tiny manufactured parts is an optical comparator. It allows the operator to obtain accurate measurements of items that are difficult to deal with due to their size. It generates a large replica of the part utilizing a scientific magnification technique using lights and mirrors. With the lens and mirror combination, the majority of images displayed on the screen are images with the same feature. It also has an edge sensor that detects the image movement direction on the screen. In this article, you will learn about the purpose of the optical comparator, its accuracy, calibration, accessories, and alternatives.

Purpose

Optical comparators make previously unfeasible precision work attainable. In the industrial sector, the smaller an object, the more challenging it is to handle. Over the years, optical comparators have demonstrated their efficacy in evaluating the quality of a wide range of manufactured components. The tool provides great assistance in niche industrial applications.

- Accurancy – In addition to measurements, further information about the manufactured item’s physical properties may be obtained. Multiple individuals can see the comparator readout and offer a means of conversation.

- Ease of Use – With a single keystroke, operators obtain a straight line distance.

- Efficiency -Optical comparators are simple to operate, with ergonomic designs that decrease operator fatigue, retraining expenses, and inspection time. They are suitable for either repetitive or first-article inspections.

Tim Allen of Suburban Tools provides an excellent walkthrough of how the optical comparator operates.

Accuracy

The system is based on an optical assembly that appropriately magnified and displayed the image’s picture. This fundamental notion has remained unchanged since its inception. Manufacturers are always incorporating new technologies into the foundation to increase the precision and flexibility of these devices. The optical comparator’s accuracy improves as glass grinding technology advances, resulting in better lenses for image projection. Similarly, because of its automatic edge detection, it makes it possible for the optical comparators to distinguish part edge. This instrument may also use computers to analyze images for more accuracy and quality output of its work.

Calibration

When calibrating an optical comparator, the most essential factors of accuracy to consider are length accuracy, magnification accuracy, and squareness accuracy. Length accuracy is critical since it affects measurements of the device utilized along the X or Y-axis. Most optical comparators have an automated edge sensor, which helps to decrease error when identifying the edge by eliminating operator uncertainty. As with other precision measuring equipment, calibration of an optical comparator on a regular basis preserves measurement accuracy. Calibration objectives differ depending on the exact design of the optical comparator as well as the planned usage of the instrument. There are standard methods and techniques for calibrating an optical comparator across all four types of accuracy, and many metrology manufacturing companies offer calibration services.

Accessories

- Fixture – Optical comparators use fixtures to position and measure the item in the proper orientation. It can fix a circular item horizontally by clamping it down. Similarly, it can fix an object whose bottom surface is not flat in a measurement-friendly position. Fixtures come in a variety of shapes and sizes, including clips, clamps, and magnets.

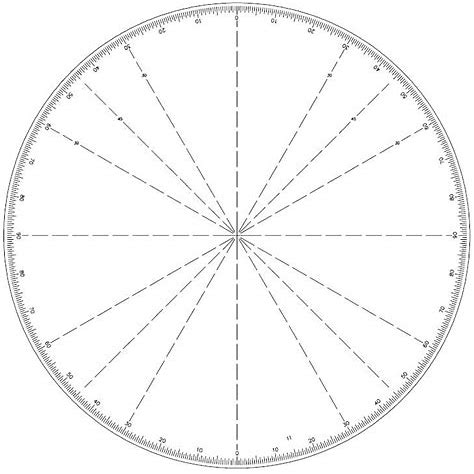

- Mylar Overlay Chart – The purpose of using an overlay chart is to match it to the projected measurement image on the screen. There are several various kinds of charts, including grid or concentric scales. Since it is magnified at the same magnification, the overlaying diagram chart can portray the appropriate design value of the measurement target.

- Surface Illumination– Optical comparator illuminate both below and above to create a shadow and project outlines. Even if the measurement target is difficult to measure with only the transmission (backlit) image, it is possible to measure it by using the epi-illumination.

- Curtain – Optical comparator may have blackout curtains that to restrict light from entering the room and block ambient light. This allows for a more precise image projection.

Alternatives

- Measuring Microscopes– These instruements are not the same as regular microscopes. Linear scales, a reticle, in-line lighting, and transmitted illumination are all features of this type of microscope. Positional input is provided via linear scales. The reticle serves as a measuring reference point. In-line lighting for reflected light applications, and transmitted illumination for contour or profile measurements. Operators of measuring microscopes can utilize high numerical aperture objective lenses, which give great optical resolution down to 1m (.000040 inch). This enables operators to detect objects with a measuring microscope that could not been viewed with any other optical measurement equipment.

- Video Systems – Video systems usually have magnification lens and camera that are relatively new to the inspection instrument industry. Compared to optical comparators, they offered reduced size and weight. They are more costly. The benefits of this type of technology often exceed these drawbacks.

- Vision Measuring Machines – these optical inspection tools are based on a platform with at least three axes and one objective lens. This gadget is generally computer-controlled and recognizes features of manufacturing items automatically. It also calculates measures from those identified features. Thus, it required software for operation.

- Laser Inspection Instrument -These devices provide the highest level of precision of any optical inspection tool. It can predict the accuracy and repeatability of +/-.0000010. By reflecting a laser beam from a feature being studied, this gadget utilizes time delay calculations to compute distances. This highly specialized form of measuring necessitates the use of a fixture to locate the laser device as well as significant setup time to position the instrument. Laser inspection instruments are excellent for a variety of industrial inspection and calibration applications.