Pipework expansion joints function as connectors in piping systems to help alleviate and dampen certain stresses. Typically they are a polymer that allows for expansion between the flanges of the joint. Depending on the type of flow in a system, different types of joints may need to be utilized in the system. Additionally, expansion joints are considered early in the assembly of a piping system and may be planned for in a piping spool drawing once the type of flow is identified. In this article, you will learn the types and functions of pipework joints, design considerations, common applications, and maintenance and repair considerations.

Design and Applications

Pipework expansion joints are designed with expansion in mind. They alleviate stresses associated with expansion due to thermal changes, pressure changes, and other physical factors of a piping system. Depending on the stresses imposed by the system flow, different types of piping expansion joints are specified. Some high temperature flows cause thermal expansion of the piping system, necessitating a joint that withstands high temperatures. Alternatively, some may only experience a corrosive flow in which the joint must be able to resist the corrosive nature of a flow and handle expansion at the same time.

Expansion joint design considers maintenance and ease of mind. Typically, they are flanged on as separated pieces to a system. This makes removal, maintenance and inspection of the joints simple. Applying an expansion joint works to counteract and withstand the expanding of a flow. Alternatively, whether it be from throttling at a different point in the system or increased inlet and decreased outlet, expansion joints are perfect for applications where pressure relief is needed in a flow. The next section covers the types of expansion joints used for different types of flow.

Types and Function of Pipework Expansion Joints

The main function of a pipework expansion joint is to counteract any negative effect of a flow in any given point of a piping system. Depending on if thermal expansion is a major concern for a section of a piping system, an expansion joint may alleviate the associated expansion by allowing this section of piping to expand. Depending on the application, different types of pipework expansion joints may be utilized. The major types are: metal bellows, fabric joints, rubber joints, and PTFE joints.

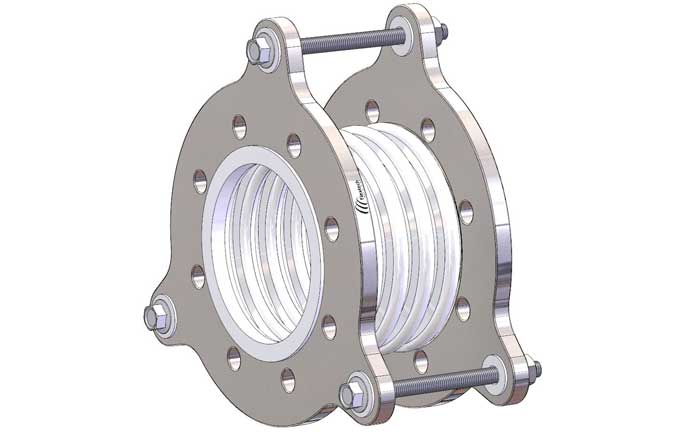

Metal Bellows

Metal bellows-type expansion joints are metallic elastic piping that compress with pressure. Their metal construction makes them ideal for high-temperature flows and they handle vibration and excessive temperatures well due to their ability to expand and hold heat. Depending on the shape of the joint needed to fit a system, metal bellows may be adjusted. Metal bellows also absorb and account for axial and angular forces. They are loaded with axial compression or tension.

Fabric Joint

Fabric expansion joints allow for the most flex in a piping system. These are ideal in lower heat thermal applications and vibrations of air and other gases. Fabric joints are a plastic-like substance that allows for the joint to stretch and easily conform to the changes at the joint in a piping system. Fabric joints have large axial movement capabilities. Additionally, they fit the shape of a piping system as well as the orientation of the joint necessary. Fabric joints are lower cost than most other types of expansion joints.

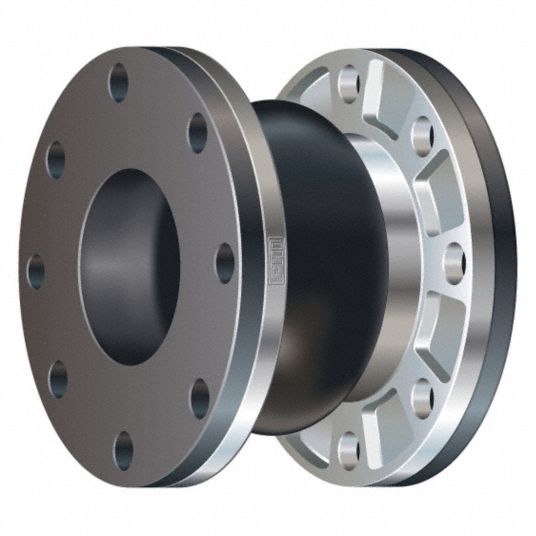

Rubber Joints

Rubber expansion joints are ideal for flows that experience medium levels of heat and viscous flows. These joints are often of use in slurry applications for their ability to handle larger particles. Ideally, maintenance makes rubber expansion joints attractive to use in solid flows for their ease of cleaning. Similarly, rubber joints are also extremely good at dampening the noise put out by a system.

PTFE Joints

PTFE (polytetrafluoroethylene)expansion joints are ideal for corrosive flows. In a flow that is chemically corrosive, PTFE joints do not react to the flow which is ideal in this application. They provide ruggedness and corrosion-resistant properties demanded by chemical flow applications. Most commonly, PTFE joints are near pumps in a system to account for any heavy changes of inlet pressure in a system.

Maintenance and Repair

Piping expansion joints are specific locations in a piping system that expand. Typically, they are in between flanges separate from the uniform of the rest of a piping system. This allows for easy removal, maintenance, and replacement. A technician is able to assess the internals of an expansion joint to determine if it needs cleaning, repairs, or a complete replacement. This makes them one of the most easily maintained and configurable components in a piping system.