At some point, the building of equipment, plant, or process requires outsourcing of engineering to move forward. This may be due to increased workload, lack of in house talent, or strategically as a business differentiator. Knowing the right job roles to outsource and the right ones to keep in house directly influence a project and a company’s profitability.

Why Outsource Engineering

Engineering outsourcing is necessitated by fluctuating demand and when appropriate talent is unavailable in house. This is particularly true in a project-driven environment with varying levels of work backlog. An equipment provider can staff up completely for the highs and allot a bunch of water-cooler time for the lean times. A better strategy is to baseline the staffing level near the low end and have a great outsourcing plan in place for when heavy demand hits.

What Engineering Roles to Outsource?

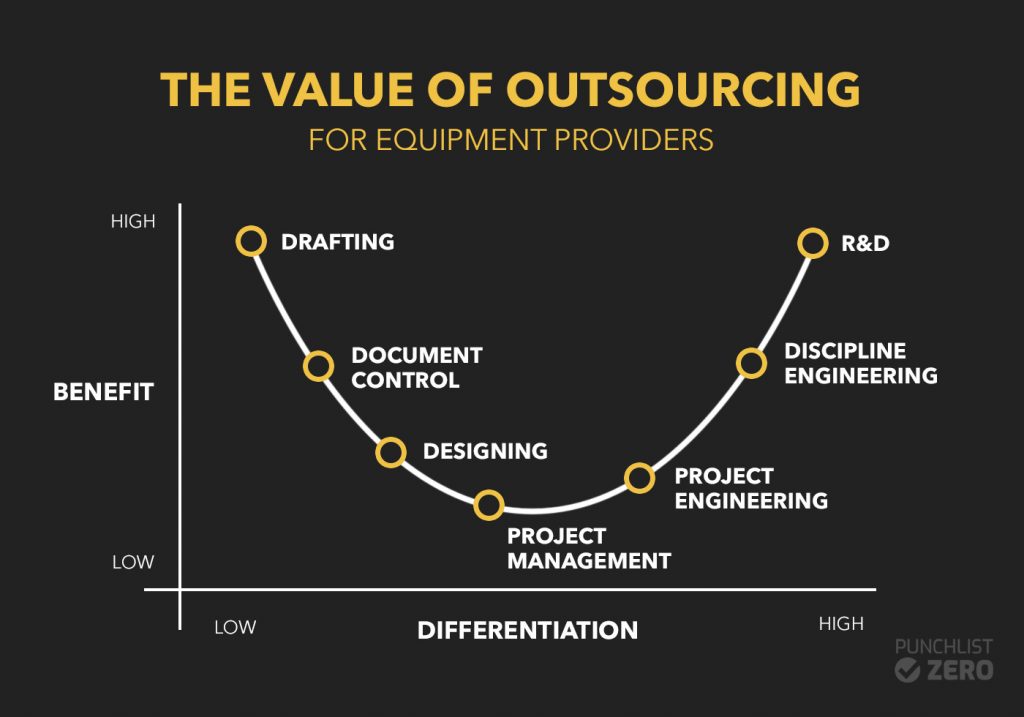

Most equipment providers have in-house capabilities to engineer, design, draft, and control documentation. Any decision to outsource should be a role-based one where individual job roles and responsibilities are carefully analyzed. Deciding which roles to outsource involves the analysis of two parameters: differentiation of the service provided and the expected benefit of pushing that role outside the company. The relationship between these two can be displayed in general terms graphically.

Outsourcing decisions usually fall into two groups: “proceed with caution” or “proceed with extreme caution”.

Proceed with Caution

The “Proceed with Caution” group covers drafting, document control, design, discipline engineering, and research and development (R&D). These disciplines may be permanently outsourced by design or outsourced on a project basis with careful thought.

Drafting

The responsibility for drafting P&IDs, G/As, or any other mechanical drawings is usually one of the easier candidate for engineering outsourcing, particularly if it doesn’t involve model work. Why? Drafters perform routine, dimensioning and layout type work and are not responsible for understanding specifications, interpreting client requests, or making strategic decisions. A drafter’s job has little ambiguity and with the guidance of a strong mechanical designer should be simple to outsource. Risks do exist. Sometimes the drafter role may provide fabrication guidance or understand specific fabrication nuances. Freelancers may not be able to provide that same project guidance.

Document Control

Controlling documents and the job roles associated with that function saw a boon of outsourcing once software and upload speeds entered the broadband era. Numerous cautionary tales exist of document control roles shipped overseas with the nuances of individual customers left on the boat dock. A successful outsource activity involves great intentionality to customer nuances and an understanding of client culture.

Discipline Engineering

Discipline Engineering refers to any specialized form of engineering. This ranges from a Professional Engineer’s review and stamping of drawings to specialized vibration equipment.

Two schools of thought exist as to how managers monitor discipline engineering. The first school considers all engineering functions as being autonomous in execution and subject to a project’s overall technical scope of work. The second school sees discipline engineering as the project engineer’s responsibility. That project engineer checks, integrates, and provides overall guidance to discipline engineers. Generally speaking, most projects operate via the second school of thought. This allows for an additional layer of checking and de-risks the process of outsourcing even further.

Designing

Designing is the process of laying out equipment, a plant, or a process in a 2D layout or a 3D model. Outsourcing this job role carries a bit more risk than the drafting function as designers carry responsibility for understanding specifications and local standards. With an in-house source removed from the project team, this duty falls to the project engineer or manager. Outsourcing the designer function requires particular care to the sharing of any block libraries, formatting standards, and model creation methods.

Research and Development (R&D)

Most equipment providers don’t spend much time on R&D and typically it falls outside project execution. R&D as a function of gross domestic product (GDP) in the United States has been hovering around 2.5% for the last forty years. If your organization spends money on R&D, it might occur at a remote lab or alongside project work. Most organizations don’t have the luxury to hire a dedicated R&D team. In those situations, the R&D function may reside as an additional duty on other personnel. Since R&D is usually separate from daily company functioning, it is one of the easiest activities to outsource.

Proceed with Extreme Caution

In most environments, the Project Engineer owns a project’s technical execution and the Project Manager owns all commercial concerns. As such, the outsourcing of either of these job roles means not just a different strategy, but a different business model entirely.

Project Management – An equipment provider who chooses to outsource commercial responsibility for an in-house project does not make practical sense. However, outsourcing certain elements of project management may make great strategic sense.

Let’s imagine a scenario where fabrication work takes place at a distant facility, Fabricators Plus. Rather than fully trusting Fabricator’s Plus to deliver as promised, a local outfit, PMs are Us, provides progress reports and inspections.

In many cases, Project Management as a discipline does not receive proper attention. Executive frequently regard Project Management as a subjective art, rather than a science. Proper control of time, scope, and cost must originate from an in-house source and any subcontract support requires thoughtful integration.

Project Engineering – The outsourcing of project engineering is fairly common. An operator wishes to procure a piece of equipment, contacts a fabrication shop and places a purchase order. The fabrication shop works with an outside firm for all required design.

However, deciding to outsource project engineering requires more consideration than specialized engineering. Having in-house project engineering talent that can provide technical solutions provides an entirely (not necessarily better) value proposition to prospective clients. An-in house project engineer usually is the lowest bar to an equipment provider having the ability to say “we have in house engineering capabilities.”

In many instances, the project engineering and project management jobs functions fuse together. This combined responsibility works well for projects with mid level complexity.

Final Evaluation

For years, firms would boast “we do everything in house!” In today’s fragmented equipment manufacturing market, this is no longer achievable or desired. Equipment providers must flexible, thoughtful, and strategic about which roles to keep in-house and which to outsource.

The key to a successful operation is a complete understanding of functional interlocks between various disciplines, both in a typical environment and specific to the organization. Outsourcing too frequently takes place reactively as a strict cost-cutting measure. By anticipating engineering outsourcing requirements and challenges, the equipment provider ensures the company and project are set up for success.