In this article, we are going to compare the U-channel vs C-channel beams, but first, we need to discuss some basics and talk about what a steel channel is.

What is a Steel Channel?

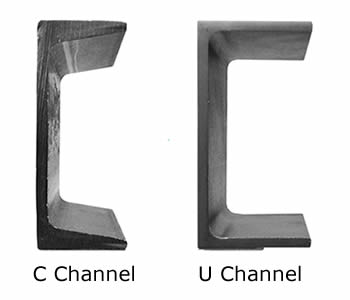

Steel channel is rolled from a steel sheet into a C shape or U shape like other hollow surfaces. It consists of two flanges and a wide web. However, the flanges can taper on one another or can be parallel. The inside corners of the steel channel have specific radii which provide strength and rigidity to it. These steel beams are easy to mold into any shape and this is where the U-Channel vs. C-Channel steel channels comes in.

Terms to Understand U-Channel vs C-Channel

There are a few terms to know before we get ahead with U-Channel vs C-Channel, which are as follows:

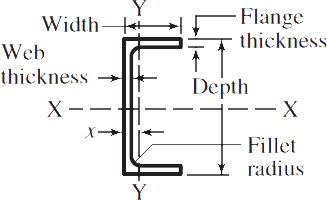

Depth

Also known as channel depth, this is the length between the top of one leg of a beam to the bottom of the other one.

Width

The width measures the overall width of the beam when in a “C” position.

Flange Thickness

Sometimes referred to as leg thickness, this measurement provides a thickness measurement.

Web Thickness

The web thickness measures the web thickness of the steel channel.

Fillet Radius

The channels have a fillet on the inside, much like other beams and angles. Manufacturers may not always provide the radius of the fillet.

U-Channel vs C-Channel – Understanding C-Channel

A C-Channel is a hot-rolled product with a C-shape cross-section on its surface. These channels have two legs connected by a web and are also called structural channels.

However, you may also find them mentioned as parallel flange channels in some places. Their webs usually have vertical alignment. The two flanges stick out from one end, which makes it easier for the beam to connect with other shapes that create a C shape.

What Can You Use C-Shaped Channels for?

The C-shaped channels aren’t as popular in use as compared to other design variations. This is because the C-Shaped channels inherently have a weaker structure. This makes it harder for the beam to bear excess weight, as it can deform under constant stress.

Thus, it is essential to use the C-Shape design only where it fits. Experimenting with the C-Shaped channels in the wrong place can cause design failure or compromise the structural integrity of a design. However, these beams usually mount on another flat beam, which can weld together. This maximizes contact and contributes to the beam’s strength.

There is still a major structural difference in the C-shaped channel depending on its production. The hot-rolled C-channels have conical flanges, whereas, the laser fused one has parallel flanges. You can determine their tolerance by ASTM a 484.

In addition, the C-Shape channels work best in industries, machinery, and equipment building. Now, let us take a look at the U-Channel.

U-Channel vs C-Channel – What is a U-Channel?

The U-channel is similar to the C- channel mentioned above with differences in its shape and applications. It is a tall, skinny, metal product that has deeper channels. However, you can achieve this depth only after rolling the metal.

A good example of this is the Aluminum U-Channel, which is widely used. Aluminum is the only metal (apart from steel) that provides U-Channels in such a major variety. The aluminum C-Shaped channels provide strength and durability, which is the biggest reason for its popularity. It also offers several other benefits and properties important to construction, which are as follows:

- Heat Treatability

- Machinability

- Weldability

- Good Finishing Characteristics

These characteristics have helped it become ideal for most applications including manufacturing a steel beam or a structural skid depending on the design requirements. It means that the U-Shaped aluminum channels are a versatile choice in the industry. Let us have a quick look at some of the most common applications of the U-Channel

What are U-Shaped Channels used for?

The U-Shaped Channels work best for metal stud ceiling systems, lightweight gauge steel structures, and drywall framing systems. For example, they work well as horizontal channels through drywall framing systems. They also fit well as main carriers and edge channels in stud ceiling systems. U-Shaped channels of different sizes can provide static loading to over 100 tons. What more, engineers may customize the application U-Shaped channels to equal or unequal shapes and design structures.

Bottom Line

When it comes to U-Channel vs C-Channel, both have their differences based on their manufacturing processes, standards, and uses. Both of them play an essential role when it comes to structuring design and building. For example, the U-shaped channel is commonly used in decoration.

This sums up our comprehensive guide on U-Channel vs. C-Channel. Make sure you reach out to us if you need further guidance regarding these channels. We, at Punchlist Zero, would love to help you out.