Newly minted engineers and engineering students usually have the same one or two questions for me:

“How do I get an internship?”

and

“What modeling program should I learn?”

In today’s post, I’m answering those two questions, but those two questions are drastically overrepresented and over prioritized by the new engineer. So I’m offering 100 other concepts, ideas, and tactics that allow you to skip the pain of a hard-knocks education. 102 ways to be a Better Engineer is a boatload of information so I’ve chunked it into six sections to make it more digestible:

- What Everyone Asks Me About: 1-2 – Don’t overthink these two, just make it happen.

- The Core of Great Work: 3- 16 – No matter your career choice, these are fundamental mindsets for a successful and fulfilling career.

- Leadership and Career: 17-37 – You signed up to be a leader when you decided to be an engineer. Here are some leadership and career principles you probably didn’t learn in school.

- Secrets of Business – 38-57 – What you need to know about the inner workings of companies.

- An Efficient and Effective Engineer: 58-79 – How to become ruthlessly better than others in a fraction of the time.

- Energy Industry: 80-102 – Specific insights into the energy industry projects and its impact on engineering and associated disciplines.

Disclaimer: This post includes affiliate links, meaning I might earn a small commission on sales at no cost to you. I only link to products that I believe in.

WHAT EVERYONE ASKS ME ABOUT

1. By all means, learn some modeling.

Don’t get overly concerned over which drafting program you should learn. General modeling principles tend to apply across different drawing packages. Solidworks is a clear first choice for the ubiquity of the platform and for the ease of use. Less typical selections such as CAD Works, PTC Creo or Revit are also a few solid selections. But if you are taking a modeling class in hopes of putting the right drawing package on your resume to win a job, it’s a bit like going to Vegas and putting your money on a number. Sure, a job may end up a match to your selected package, but likely not. The real value of learning modeling is understanding conceptually how 3D models come together and getting a taste for the art. And who knows, you may love it!

Take something cheap online. Udemy.com is really useful and costs a fraction of a dedicated class through university.

2. How can I get an internship?

If you polled every engineered equipment provider in the nation, probably 75% of them would welcome an intern. Yet, the actual number of interns hired is probably 15% of that number. Why? Internships get lost in the shuffle of competing priorities.

The best way to get an internship is to make yourself a priority by communicating early and often. Establishing a relationship with a hiring manager of the company by making smaller asks – “Do you like being an Engineering Manager?” “What would you advise be to a student in my position?” creates dialogue. Dialogue creates a conversation. Conversation creates a relationship.

This is the number one thing that new engineers and engineering students miss, maybe because they are watching too many “multi-millionaire” Youtubers. Getting an internship requires early and often planting of seeds and if your grandpappy isn’t Boones Pickens, start planting.

And know what a successful engineer looks like when you encounter him on the street. He probably isn’t rolling a Rari. He’s more likely to be sporting cargo shorts from the turn of the century, a drool stained Oilers shirt, and uncombed hair. Mid-career, he probably carries the pride of engineering degree with the same blasé sense of accomplishment one might get from remembering to take out the trash.

Just saying.

THE CORE OF GREAT WORK

Whether you become the world’s foremost engineering expert on vibration modeling for aeropace or never use your engineering degree, there are several core elements to great work. These principles apply where you pursue a career in engineering or something completely different.

3. Be impeccable with your word.

I once mentored a young college grad on his newly launched startup. We had a meeting scheduled and I checked his site traffic a few hours prior to our meeting. Organic traffic was non-existent. I lounged deep in my chair at the co-working space that day and flicked a casual question,

“How’s it going?”

“Great! We are getting thousands of organic visitors every week. It’s amazing!”

“You want to try that answer again?”

He insisted, contrary to every metric that his team was driving tens of thousands of visitors every month to the site – a blatant and easily unraveled lie. I continue to be friendly with that person but have never reached out to him again intentionally. That startup founder will continue to attract the wrong type of people as long as he manufactures his own false reality. But, being impeccable with your word goes far beyond dishonoring the truth. If you tell a vendor you will get back with him, get back with him. Don’t use words to berate others or push your pain and discontent onto the nearest and most convenient target.

4. Know thyself and to thyself be true.

For the first few years of my life, I sat in a cubicle and designed electric motors. Mediocre work resulted, because I wasn’t passionate about electric motor design and definitely not electric motor vibration nodes. After three years of laboring as a decent, but most definitely not great engineer, I jumped ship to a start-up and loved it. At one point in my career I started to refer to myself as “a former engineer”. It’s a silly box to put yourself in.

Read Also: What are the bonuses in the Sweet Bonanza?

The world loves to define people as “smart” and “dumb”, “good” and “bad”. The greatness and messiness of life can’t be defined by a label. You became an engineer for a specific reason. Maybe you are the curious type of engineer that loves to build things. Maybe, like me, you like engineering because it gives a logical and helpful system for a messy world. Whatever the case, its far better to understand yourself, your motivations, and what you are seeking out of your engineering degree. Never optimize on someone else’s idea of what success looks like.

5. Happen to life.

We are all together in not knowing what the future holds. Sometimes you are the bug, sometimes you are the windshield. How people act, macro-economies trends, and the vast majority of work-related decisions are outside of your control. How you respond is completely inside your capability. One of the best ways to tell if someone will be successful in a job (particularly in a startup) is to determine what science calls the locus of control. People who have an external locus of control see events happening to them. “I got laid-off.” “I can’t find a job.” People with an internal locus of control see their worth and outlook as decoupled from arbitrary company actions. The “I got laid-off” narrative becomes “I got a golden opportunity to start the business I’ve always wanted to build.”

6. Have an extreme bias for action.

Always push the load. When you are stopped, keep the wheels grinding. Phone a friend. Talk to a subcontractor. Get a business coach. Take a break and look at it from a different angle.

You want to know a secret?

Organizations generally assume that solving hard problems is 25% hard work and 75% domain expertise. They are wrong. Solving hard problems usually is 95% pushing the load and 5% domain expertise. What does this mean practically? Be or hire the person who always pushes, smartly, creatively, and patiently. They will solve the problem while a dogma loving expert and their entrenched thinking knock on the same door over and over.

7. Play hard, but play loose.

The second greatest quarterback of all time, Joe Montana, was leading the 49ers in the Super Bowl and trailing 16-13 to the Bengals. The stakes could not be higher. The 49ers are huddled when Joe spots the actor John Candy in the stands.

“Look, isn’t that John Candy?”

The silly offhand comment shifted his team’s attention momentarily from the task at hand and gave them a cognitive break from extreme pressure. The slight cognitive break mattered, but the message of complete unflappability from the team’s leader calmed the team. The stakes were never too high to rattle Joe and less than an hour later the 49ers were champs.

There’s such thing as being too professional in the workplace. Much like obscenity, you know it when you see it. The too professional guy is afraid to crack a joke and wants desperately you to know how hard he is trying. Relax friend and just go execute.

8. More is not always better.

A lifetime ago, I worked at a startup where talk centered around hours worked as a badge of honor. I bought into the arrangement, frequently clocking 70+ hours and opining with my co-workers we were pushing ahead of our peers and learning so much.

Then I read a research study that discussed how people’s productivity plummeted after 55 hours a week. I started observing my coworkers a bit more carefully. How much work were they really doing? The result of this anecdotical study was…not as much work as you would think. There were a lot of smoke breaks, wild pontification about minutae, and mostly people with melted brains and no energy to sprint.

That’s not to say that you don’t have to work crazy overtime from time to time, relax and play video poker free on line instead. To make a deadline, to ship a product, to satisfy an important customer. That, however, should be the exception rather than the rule.

And don’t bring up Elon Musk here. Homeboy runs 2 or 3 companies. Those 80 hours weeks drop to 40 if he just chooses 1 company.

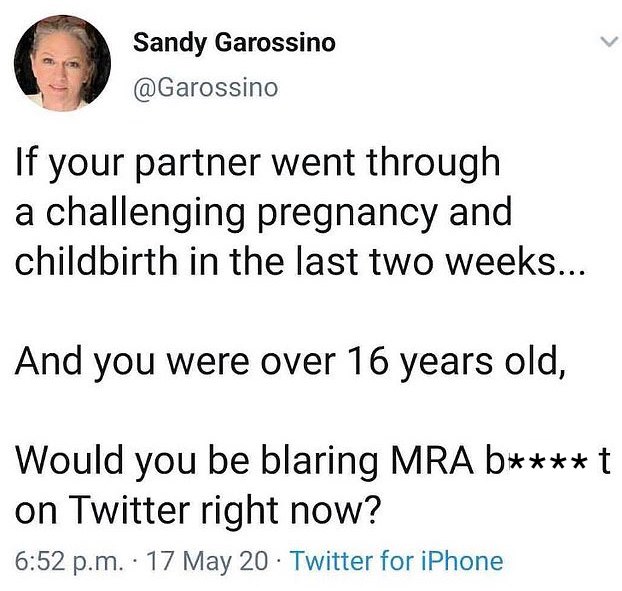

Plus, this is what his mother-in law said about his parenting skills.

You don’t want your mother-in-law to put you on blast. Be there for your family. Speaking of…

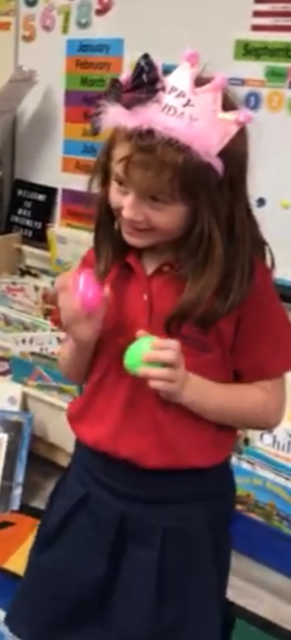

9. Go back for the tiara.

My kindergartener celebrated her 6th birthday recently. We dropped her off and forgot the special tiara my wife bought for the occasion. We were 5 minutes from the school and doubling back equaled 10 minutes I didn’t have. Annoyed at the inconvenience, I started to fire off the reasons we couldn’t return go back until I paused, and said, “Ok, you are right.”

And later that day…

I’ve long since forgotten the proposals and the calculations of that day. But I’ll remember her joy long into the future.

10. Don’t complain.

“I just need to vent.” No, you really don’t. The science behind complaining and its impact on morale show that complaining is pretty terrible for you. If you find yourself consistently complaining and dreading work, find another job bud. At one point in my career, I found myself talking far too much about our drunk and frequently tardy CEO, Bob. By making one of my metrics “no complaining” my productivity and job satisfaction skyrocketed.

11. Extreme Ownership.

I worked with a highly talented project engineer who spit out highly accurate P&IDs and datasheets all day long. However, he was overly reluctant to get involved in the technical details of any of the supporting disciplines – be it structural, vessel, or electrical. As the project manager, this frustrated me greatly. This project engineer had the technical know-how to add a layer of insight on the project but simply would not because he did not see it being in his job description.

“That’s not in my job description” might be the most annoying thing an employee can say. All great work is done stems from hard work applied to curiosity in a way that can never be captured in a job description.

12. Your degree is for thinking.

Hang around a practicing engineer for a bit and you will hear a lot about how a real-life engineering degree has little applicability to the work an engineer actually does. I understand that sentiment to the point where I birthed punchlistzero.com to bridge that gap. But the best thing about any structured engineering program is it teaches you a superior way to process information.

- Carefully understand the problem.

- Create closed boundary conditions.

- Determine inputs to the problem.

- Structure a path to a solution based on available data.

- Work out a solution.

Apply this engineering process to all of your life decisions and watch the quality of your decisions increase. A brain steeped in cause and effect decision making properly weighs available opportunities and makes better decisions.

13. Know the customer’s true needs and be sure they are satisfied.

Knowing the customer’s true needs may not be immediately evident and typically vary from the customer’s expressed needs. These needs may be masked a subcontractor that provides a specification that is just not quite right. The customer may not fully understand available technological needs.

Steve Jobs was famous for eschewing focus groups and surveys and nonetheless building delightful, customer approved works of art. Sloppy explanations for Job’s success abound: he’s a genius, he’s a jerk, he works a lot of hours. Many of those reasons are fractionally and tangentially true, but Job’s success was largely due to his fixation on the customer’s real needs. Needs that were not even apparent to the customer themselves.

One time, a customer wanted my company to build a transport tracking system from the ground up. I researched available options and realized that what my company could provide would only meet the best in class standards of the marketplace, but at a price tag of 4x. By telling the customer as such and placing a no-bid, I built greater trust and eventually led to more work in the future. But even my no-bid brought no additional work, it was still the right thing for that customer.

When a customer lends you your trust, particularly as a technical expert, never give them any reason to doubt that trust.

14. Safety is paramount and you are a key piece of it.

My Dad grew up fatherless because of a workplace accident. One weekend, a coworker hooked up a drive improperly and killed himself. Adam Weise and I drank beers over Christmas break and four months later his life was ended when Deepwater Horizon exploded.

As an engineer, you are the vanguard. Project managers, finance guys, your customer, and everyone else wants it quicker, quicker, quicker! Most organizations in this era do a good job of setting protocols in place that emphasize a safe working culture. But engineers have a special professional obligation to analyze the systems they design and ensure that we all return home to our families. What that means in real-life is speaking politically inconvenient truths to leaders who don’t want to hear them. You might lose organizational clout or put your job at risk, but you will prevent senseless tragedies.

15. If you get what you want it might kill you.

Don Miller relates the story of a rabbit chasing a carrot. The rabbit chases carrot around the globe and even to the moon. After this huge amount of effort, the rabbit finally catches the carrot. The moral of the story? If you work hard, stay focused, and never give up, you will eventually get what you want.

Unfortunately, there’s a second moral of the story. If you get what you want, it might kill you.

Maybe there’s a guidepost in your life that makes you want to eschew all practicality and “go for it”. Be it a title or occupation or salary. Its seems like the human trade-offs are worth it at the time. But as anyone can attest, anything worth striving for is not only well worth the struggle, it’s an incredibly larger time commitment than projected. And it may not even be what you want either….

16. Seek humility

If you are a new engineer, you have a lot to learn. If you are an old engineer, you have a lot to learn. My arrogance peaked at age 15 where I formed a Travis Ziebro fan club on the sketchy basis that I was the best basketball player in the neighborhood. Since that zenith, consistent humbling in all areas of life have followed. If you aren’t be consistently humbled, you aren’t trying enough things and making enough mistakes.

No matter where life takes you never be Engineer Dave. Engineer Dave sat in his cubicle and knew code and flexed hard on co-workers when they didn’t know engineering minutiae. Great buddy, you are a real winner. Made the Document Control Manager cry multiple times, but you knew the corrosion rate of 316L hardware in a salt-laden environment. Write that on your tombstone.

LEADERSHIP AND CAREER

Many years ago, Charles Barkley made news when he said, “I’m not a role model.” Guess what? Certain things are out of your control and when you are playing professional basketball, becoming a role model is the by-product of the territory. And yes, that’s what you signed up for when you got that engineering degree.

Frank Sinatra famously opined that Love and Marriage go together like a horse and a carriage. If Frank was more engineering-focused, he would have said Leadership and Career go together like a horse and a carriage. It’s impossible to even a mildly successful engineering career without being a technical or people leader. Let’s explore a few ideas on how to achieve success in both arenas.

17. Don’t flex, but if you must, flex gently.

Never make a subordinate or colleague look bad in front of other people. During a meeting, I berated a bill of material entry engineer in front of THE MENTOR. “How could this happen again?” I scowled, drawing out “again” for a solid second with an icy stare.

Later, behind closed doors…

THE MENTOR: “Why did you do that?”

Me: “Josh was wrong.”

THE MENTOR: “He was wrong, no doubt. But you questioned his fundamental engineering skills in front of everyone. Why? What did you hope to accomplish?”

Me: “….”

I had no answer because I flexed only to demonstrate my knowledge and power. A better response to Josh would have been:

“Ok, we want to be focused on hitting our deliveries because overall we are 43% on time performance. So how can we support you to make your goals?”

That gentle prod takes direct aim at subpar performance and directs it to better performance.

18. Break free of invisible social/company forces that muzzle your voice.

It’s typical to worry what your employer might think about your candle-making obsession or DJing business or really anything that’s atypical of the company’s standard operating culture. In some environments, personality is tamped down. Say this, not that. And while this tight content control might be the case, typically the company cares way less than you think they do. And if they are really concerned about you dabbling in bird watching or writing a personal article about leadership experiences, then maybe you should work for a different company.

And also, don’t be that guy in everyone’s LinkedIn feed who reshares a really bland article about his company’s new heat exchanger design without context and commentary. Those careful, overmeasured efforts at professionalism lack creativity and are bad marketing. Maybe your company should just spool up a Twitter bot and just call it a day.

19. Meetings are for losers.

Well…ok not really. But now that I got your attention, there’s nothing that’s worse for productivity than excessive and improperly planned meetings. The sloppiness in planning and executing meetings would be comical if not for how crippling those meetings can be to productivity and morale. Too many attendees? No agenda? Discourse that meanders for hours?

Far too common.

The work of an organization should be done outside of a meeting 90% of the time. Plan any project meeting carefully, avoid large meetings unless they are well run and thoughtfully executed. Don’t be afraid to politely dissent if you find large swaths of time being eaten up by meetings talking about meetings.

20. Flip burgers.

Look, no post-graduate hiring manager wants to be your first job. There’s a tremendous amount of responsibility gained from showing up somewhere and slogging through unappreciated and grueling work. You learn about managing conflict, keeping to a schedule, responsibility, and other cliches that your mama taught you. The interview was going well with the soon to be mechanical engineering graduate at Texas A&M. And then I asked him about past jobs.

Nothing. Whatsoever. His parents and he prioritized slews of extracurricular resume building activities and goat yoga over…you know…real work. Not one time did this guy get up at 4:45 am to put frozen chickens on a spinning stick or did his boss forget to tell him to come in at midnight instead of 5 pm because the cemented stabilized soil pour was happening at 3 am so he had to work 18 hours straight.

Getting kicked around at a menial job is 50x the future career value of enhancing flexibility with goats.

#endoldmanrant

21. Communicate clearly and often. Then repeat.

In project management, one key and seemingly counter-intuitive tenet is “the burden of communication is on the sender, not the receiver.” This forces clearer communication and eliminates blame shifting to the recipient. Project managers, engineering managers, and task owners must express clear thoughts backed by concrete actions and commitments.

If you are communicating a message always make sure it is overcommunicated. Because you will invariably think your team knows what you mean and they won’t. Just saying that I might have done this a few…hundred..times.

22. Play the right kind of amount of politics.

There’s usually two outlooks on politics at the workplace. There’s the purist taking great pains to say “I never play politics. What you see is what you get.” And there’s the backslapping good ‘ole boy who is quick to compliment anyone that’s aligned with his interests at that particular time.

Both of them are wrong. The purist loses sight that telling the blunt truth about everything is not always beneficial for the company or the career. Some battles simply are not worth fighting and something “correcting a wrong” is out of touch. The backslapping good ‘ole boy eventually falls victim to karma and if he doesn’t, his career is full of hollow victories, one of self-exultation rather than building up his peers and employees.

As Ryan Holiday says, moderation is the highest form of greatness. The ability to see grievances on either side and choose the appropriate battles to engage should be one of the highest marks of an engineer. Listen, absorb, and engage when the material and importance of the matter demand it.

23. It’s better to work for a great boss at a crappy company than a crappy boss at a great company.

I’ve worked for one really bad boss, a boatload of decent ones, a few good ones, and two great ones. You might realize the great ones are great from Day 1 or be slow on the uptake like me and not realize it until years later.

Major characteristics that great bosses have in common: they feel your pain, they have a vision, they want you to be better, and their ego is absent. As a young engineering manager at a company on the doorstep of bankruptcy, THE MENTOR took significant pains to ensure the appropriate support personnel were available to help me personally succeed. He was highly sensitive to what success looked like for the company, while being self-deprecating and challenging me in ways that stretched me.

While working at a major corporation with a healthy balance sheet, I labored under a really bad boss. He threw me under the bus in the middle of meetings, gave poor and incomplete direction, and lacked any opinion other than the beliefs of his boss. The vilest moment under his tenure was where I gently questioned a sub-optimal process. The really bad boss launched into “You are the most disrespectful employee I have ever met!”

24. “The three most harmful addictions are heroin, carbohydrates, and a monthly salary.”– Nassim Taleb

For years I watched my salary grow and 401K swell. It gave life a nice tempo and brought a feeling of security. Then I started my own firm and was roughly jolted to the poverty line. Leaving that paycheck was incredibly tough, but my personal growth while making little money could not have been made in any other context. Money can be a salve to our worries, patching over deeper issues, and preventing many from seeing their purpose. Two of my buddies are highly successful engineers with well-paying jobs they hate. I know someday they will do something more aligned with their purposes, but swimming out of the muck is proving to be incredibly difficult.

Watch the trap.

25. Engineering management is tougher than regular management.

Any type of people management is challenging, but the technical bent of engineering management adds an additional layer of complexity. Many fail in this situation by being too heavy-handed with the technical end of the business or too lax. Heavy-handed managers check every drawing, are inflexible on protocol, and insist on everything being done their way. This centralized decision-making structure makes company growth difficult. A lax model is frequently is usually characterized by the engineering manager constantly saying “I’ll have to talk to my team on that one.” Many leaders are too quick to characterize themselves as non-technical. An engineering manager doesn’t need a Master’s in Structural Engineering to run a successful department, but they do need to be technically sensitive, no matter their background. Meaning understanding of how technical specifications and design tie into commercial decisions is an absolute must.

26. Manage to a tripod of Key Performance Indicators (KPIs).

Key performance indicators are a guidepost to what’s important. Each department should have not one, but three. Why three? An organization gets the performance it incentivizes. Measuring personnel to one metric such as drawing performance sways priorities too far in a single direction. I once worked at a fabricator where the on-time performance was the only metric. Guess what got delivered? On-time drawings that were sloppy and rife with errors.

Having key performance indicators with two dimensions rather than one can also work. For designers, I typically like to see metrics like drawing quality, on-time delivery, and internal change orders. The drawing quality metric expresses errors, the on-time delivery ensures speed, and any internal change orders placed against the engineering department show not just the number of errors, but how impactful those change orders were on a dollar basis.

27. Listen.

There’s always some fool that has to have the last word in a meeting. He’s got to look the smartest, have the best question, and the strongest rebuttals. I’m putting my money on the quiet listener in the back of the room, silently observing power dynamics, possible solutions, and doing mental math on the right way forward.

28. Understand how to deliver bad news.

Too often people hide their true words about co-workers, employees, product strategy, and basically anything happening at the company. Someone who stands up to tell a co-worker “You are underperforming and here’s why” is rare and incredibly valuable. Managers too often watch incompetence in motion and their silence rubber stamps mediocrity. If you don’t have the guts to speak truth into bad situations you are an accessory to theft. That’s not only the theft of company time, but theft of that person’s potential.

Because delivering bad news isn’t just good for you and your company. It’s also good for the receiver of the bad news. Once I terminated a 19-year-old shipping employee for insubordination. He came back to office a year later, now employed at a new, well-paying job. He shook my hand and said it was one of the best things that ever happened to him.

Always choose five minutes of discomfort over years of sub-optimal performance.

29. Find the side door.

When you talk to most people about finding a job, they use the number of resumes sent out as a barometer of how hard they are trying. As a hiring manager, that’s probably the worst metric a job seeker could use to gauge potential success. Many jobs are opened for months and the hiring manager may not even look at a resume for weeks. Some companies open job requisitions aren’t even hiring for political, compliance, or appearance reasons. In short, there’s a large likelihood that your great resume goes completely unseen.

A better metric? How many contacts have you made with the hiring manager directly? Don’t have a great network yet? No worries, between Google and LinkedIn, its amazing the number and quality of connections you can make. One of my good friends got laid-off from the upstream industry. His response? He built a website, published content identifying himself as a marketing expert, found the hiring manager of a job in a different industry, and made contact. The result? A nearly immediate job offer while his peers floundered.

30. Network. But do it wisely.

At the beginning of my career, I’d go to these large, nebulous “networking events for new college grads.” It’s cool to meet people. I met people for years at “networking events” and can’t recall doing any business from it. Why? Serendipity aside, generic networking with people who are lumped together by age or industry is a pretty dubious value proposition. Skip the cocktails and reap the benefit of networking as a by-product.

I took Dunder’s Data machine learning class and met several interesting folks who shared my passion for technology. Today, I’m in Dunder Data’s Slack channel and there’s always interesting insights from these former machine learning students that one could never obtain from anywhere else.

At an ADP compliance seminar, my CEO and I groused over some of the silly guidelines. We found a sympathetic ear from a fellow attendee and CFO of a manufacturing firm. My CEO and I would end up hiring that that CFO on an advisory basis and I eventually worked for him at another company. Thanks, Big Bank Hank!

31. Don’t have a job? Work for free or design something and share it.

People want to work with folks they can trust. It’s hard to build that trust when your online presence consists of Instagram pictures of high school escapades and a minor traffic ticket you got in college. Play the long game, design something cool, write a blog post for an industry resource. Telling an interviewer you have a certain degree of knowledge pares in comparison to an extensive online repository of that knowledge.

Imagine you are hiring a new engineer. Would you rather hire an engineering student that spent their summers doing goat yoga or writing technical articles on critical engineering equipment?

32. Take a class in programming.

I’m not talking about Matlab. It’s a cool calculation tool that certainly provides you with greater understanding than not coding at all. I’m talking about coding languages that are used for enterprise software and web development. There’s no right answer here – in the dawn of COVID there was even a huge run on COBOL programmers, a language that clocks in at over 60 years old.

But why code if you don’t intend to actually use it in your day job? You learned a lot about physics that you will never use in your day job. And just as physics is a chief building block of engineering, code is the building block of the virtual world. And the divide between the virtual and real world only continues to blur.

33. Take a chance!

When they interviewed a bunch of old folks, one of the top regrets was not taking enough career chances. Look around and you see scared people working a job they hate. “Just trying to make it to Friday!” “Living the dream!” There’s the angry supply chain guy that likes to pick petty fights with the operations manager about inventory. The defensive Document Controller who is petrified to lose her job that’s she hates anyway.

If you hate your job, formulate your exit plan right this second. Folks who live rewarding and interesting lives didn’t build those lives by working in a windowless box, watching the seconds tick off their lives. Grip it and rip it.

34. Find a disparate ecosystem and infiltrate it.

People tend to rotate inside echo chambers with others who think, act, and look like them. That’s a shame because some of my best learning experiences about life and as an engineer have come from professionals in deeply different places in life than me. In my early 30’s I managed a project for an equipment provider whose EPC project manager was in his late 70s. Objectively the guy was mostly a jerk, but his no-nonsense outlook and fixation on good process positively affects me to this day.

I’m fortunate enough to call several newly minted college graduates my friends. Cultivating a diverse group of contacts gives you a more informed and broader definition of career success.

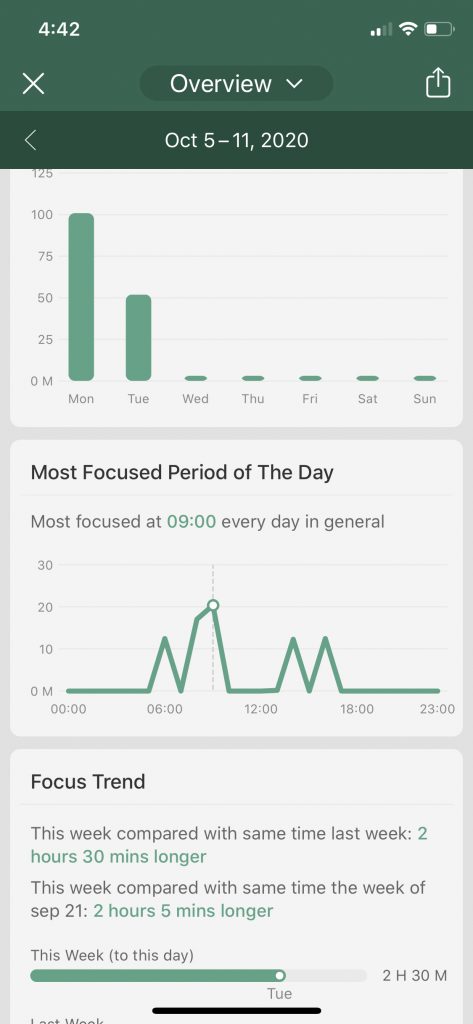

35. Be cognizant of where your time and energy goes.

One of my favorite/most hated features on the iPhone is that infernal “Here’s how much time you spent on your phone.” It can be a little depressing or viewed positively, as a built-in productivity tool. Study after study shows that a phone that is out of sight tends to be out of mind. And the mind is free to focus on deep work – the kind of work where flow state and amazing results are delivered.

Being here now and fully immersed in the challenge is almost a superpower. One of my best co-workers never worked over 40 hours a week. What Anita accomplished in those 40 hours humbled our entire department. Her energy was completely directed to her projects and while cordial, her time for idle chatter was nil.

If you have to keep your phone nearby, there are apps for that. One I like to use is Forest. You set a timer for a certain amount of time and if you don’t use your phone during that time, a small tree grows. This small cognitive burr pushes your mind to think of the phone as being off-limits. Working in these highly focused, short bursts is a strategy known as the Pomodoro Technique.

Understand that your brain runs on energy and that energy wanes and cycles throughout the day. So build a schedule accordingly. The morning should generally be reserved for high cognitive loads such as writing blog posts, programming, or performing calculations. Put your meetings in the afternoon whenever possible.

36. Ruthlessly kill your project list.

Organizations and individuals struggle mightily with this task. Prioritize 10 different projects and you will push each one 5% of the way. Prioritize two and the same amount of energy puts you ½ way done with each. A few minutes every day on planning, prioritizing, and discarding projects pays off in droves.

As for myself, I meet every other week with a coach to make sure I’m prioritizing and pushing toward my goals in a resource-efficient way. Adding more items to the to-list is something I do only with great deliberation and planning. My best workdays always start with a handwritten list of 5 top goals for the day.

SECRETS OF BUSINESS

In one of my earliest meetings with THE MENTOR, he confided to me, “Business is a game.” I found myself unsettled. A game? Wasn’t business something supposed to be serious stuff?

A dozen years have passed since THE MENTOR’s fateful quote its now clear he spoke unequivocal truth that day. Business is a game with opaque rules of engagement and undetermined outcomes. Learn the rules, learn the game. Here are a few.

37. Better to push the ball than not move at all.

Great CEOs were found to make decisions earlier, faster, and with greater decisiveness than their peers, a lesson that can be directly applied to engineering. Excessive deliberation is tough to overcome for engineers, who spent years in university studying and learning ultra-deliberation.

Quick and decisive decision-making in an engineer looks like the following: calling a vendor rather than waiting on e-mail, building a plastic prototype rather than a fancy one, and above all knowing when to stop engineering. Excessive engineering is a weakness held by many in the profession and doesn’t provide a tangible benefit versus simply meeting the project specification. Most times, good enough is indeed good enough.

38. It’s not a meritocracy. Not even close.

A meritocracy means that the best people get promoted and hired. While many companies make a noble effort to ensure hiring, promotion, and firing practices are fair, the smartest and best employees don’t always get the job or the raise. In many instances, the least objectionable candidate scraps to the top. Hopefully, in addition to being the least objectionable, they truly are the most talented.

Once you start dealing with the upper echelon of “talent” you might discover there’s a disappointing ratio of corporate drones to true leaders. The corporate drone smartly perceives the organization’s objectives and tailor his views and ideas so they meet neatly with his boss and political convenience. The corporate drone probably hasn’t taken a real risk in his job, personal life, or any avenue. He stands for whatever his manager believes in and toes the company line.

For a dedicated engineer with a passion for the “right” answer, corporate drones are tough to deal to handle. Seek out true leaders who are committed to making the best possible decisions for their company and team. Learn from them. But realize the drone tribe in average organizations typically wields a lot of power. So swallow your tongue and maybe be a bit political because…

39. The hammer will fall.

During the Great Recession of 2009, layoffs began in earnest at my employer. The Engineering Manager, close to retirement, shocked me when he said, “It happens all the time, but you never get used to it.” It happens all the time!?

Since that company, I worked for three other equipment providers and saw the following:

- Company 1: Dissolution of the division, 50% layoff

- Company 2: Bankruptcy, Liquidation of Facilities

- Company 3: Extreme cost-cutting, 30% layoff.

The hammer will fall and if not on you, on your friends, family, or a really talented co-worker that makes you think, “YOU, of all people got laid off!!?”. A layoff is full of silver linings. As someone who has been laid off multiple times, each layoff humbled me, steered me closer to my ideal career, and helped me realize the temporal nature of careers in a way that smooth, upwardly focused job movements never could.

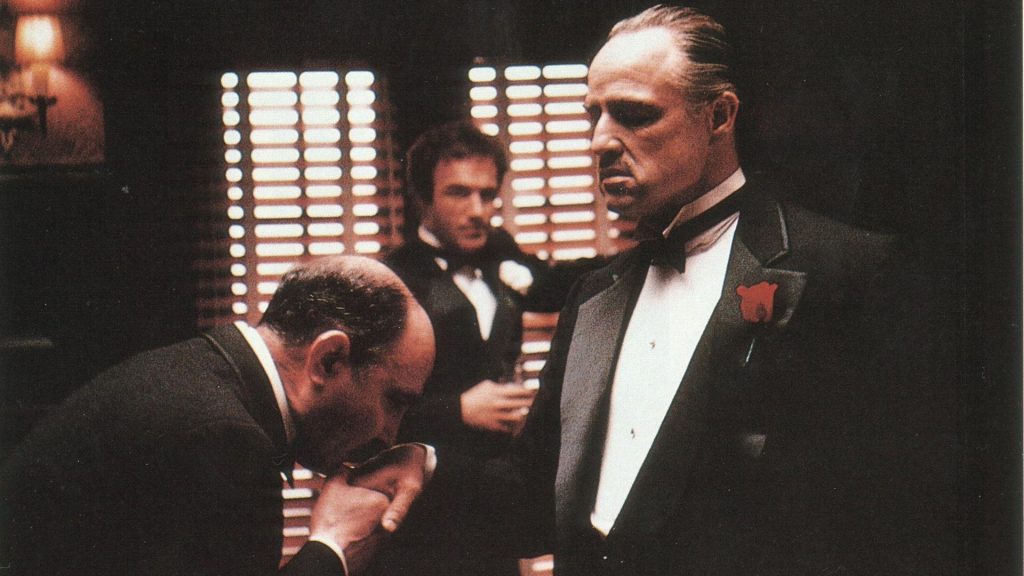

40. Understand power dynamics

There’s two kinds of organizational power – what the work chart says and the person who is really in charge. Early on in my career, I took a project manager role at an equipment integrator. In my first meeting, a gruff salesguy barked at orders at the project manager. The project manager acquiesced to every demand of the sales guy. After the meeting I went back to my newly issued workchart and gawked. The salesguy was…a salesguy. He had no formal authority but ran the place like he signed the checks.

As it turns out, Norm, soon to be dubbed as THE DON, had a simple title of salesman, but personally recommended three friends into project manager roles. With 35 years of experience, THE DON’s power over the organization far outstripped any formal work chart.

41 “That’s the way we’ve always done it” could be smart.

I worked with a designer at a rapidly changing company who often said, “Change for the sake of change is dumb.” That quote resonates with me every time leadership changes and immediately the new leader disparages his predecessor and promises a new way. Ok, buddy, glad you have all the answers and life is so white and black.

Maybe the old way is ok. Maybe the reason the engineering drawings were so bad isn’t that the process is broken, but the right person was not doing the drawings. Sometimes the old way is a good way. Sometimes, rounding up a bunch of Six Sigma Blackbelts who never smelt a diesel fume in their life to optimize your manufacturing process isn’t the right move. Sorry GE. 😛

42. “That’s the way we’ve always done it” could be an opportunity for improvement.

On May 31st, 2009, Air France 447 took off from Rio de Janiero bound for Paris. Shortly after 2am in the morning, the plane entered a patch of sleet and hail. The pinot tubes that measure airspeed collected ice and began reading incorrectly. Sensing these readings, the autopilot disengaged, forcing manual control. In an effort to control the plane, the pilots inadvertently increased the pitch of the aircraft to 13%. The pilots became inundated with conflicting warnings and ultimately began to increase the climb by 7,000 ft/minute, far more than the recommended 2,000ft/min to 3,000ft/min.

The aircraft far exceeded the angle of attack and the plane stalled. After it stall, the plane began to fall at a rate of 10,000ft/min, the hitting the water at 2:14am. The pilots experienced cognitive tunneling, a blindness effect where the focus on a small number of variables blinds an individual from the big picture. In this case, the misleading airspeed reading triggered a chain of events that ended in tragedy.

Cognitive tunneling is the phenomenon that causes smart, successful managers and employees to trot out the well-worn line, “That’s how we’ve always done it.” It causes myopic decisions that led to financial tragedy for companies. So how can this be avoided?

43. Build mental maps for the future rather than plans.

I made thousands of plans that never came to fruition. I was going to marry one or two lovely ladies in the second grade. I was going to be a wideout for the Houston Oilers. I was going to be a CEO here, a V.P. there. But life is never linear. Companies bankrupt. Pandemics strike. Financial markets collapse. The difference between those who stay knocked down and those who don’t is the flexibility to adjust plans on the fly.

Sully Sullenberg was beset by a far more daunting scenario than the faulty instrumentation experienced by Air France 447. Immediately after take-off, a flock of geese destroyed both engines. Could he keep flying? No. Could he make it back to the airport? No. What’s the next best possible scenario? Crash-landing in the Hudson. Sully’s plans were to fly to North Carolina that day. When he encountered an extremely deadly situation, he mentally mapped all possible outcomes and saved 155 passengers by ditching his plane in the Hudson.

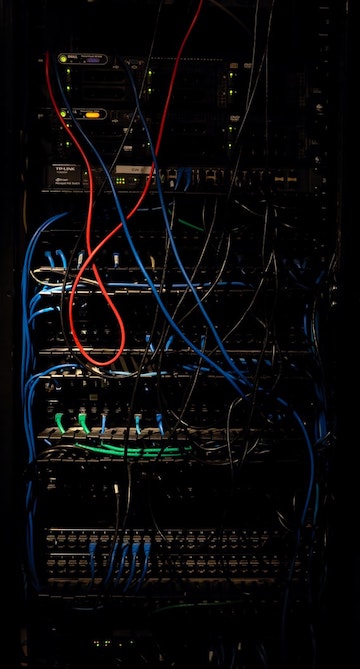

44. Understand cloud architecture

Back when the cloud was fluffy matter that drifted overhead, I managed an IT department with bubble gum and duct tape. The local server was always going out, there were weird remote terminals going into one machine and out another. I was always calling our contract IT guy in to spool up something or another.

When the cloud became more prevalent, I shed no tears for the duct-taped servers. Understanding the basics of how servers are spooled up, allocated, and matched to a needed application helps any engineer understand data storage and transfer and even can be a key element of a company’s competitive strategy.

My college roommate cooked pork chops one night that were so well seasoned and juicy I was overcome with emotion. I screamed at him inches from his face “YOU HAVE REDEFINED PORK CHOPS.” That’s what the cloud does for data storage and I feel every bit as passionate about as it as I did those pork chops.

Not sure where to start? Udemy has some great classes in general. I took this course on solutions architecture and highly recommend it.

45. Have a side hustle.

Engineering is a demanding profession and carving out time that you likely don’t have to make money a different way might be a tough sell. But look at it this way: job security is today’s market is…not always great. From learning how to sell, to understanding a client’s needs, to simply lining the bank account with a few extra dollars, a side hustle pay dividends for your education, future, and confidence. For years, I ran a DJ business, stacked a bit of extra cash, and learnt some incredibly valuable lessons.

46. Understand modern marketing.

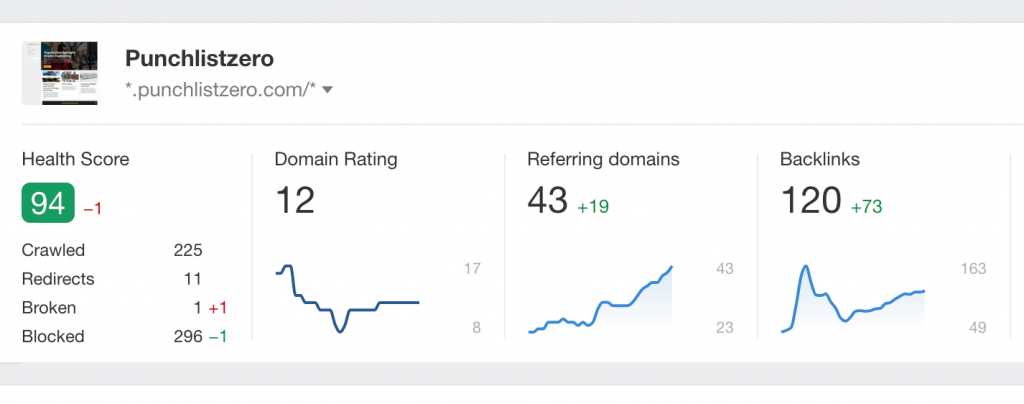

Understand modern marketing and you gain a superpower because most engineering-related disciplines are stuck in the 1980s. Money gets thrown away on tradeshows and koosh balls as their website limps along. That’s lazy marketing and you have an obligation to help your organization understand today’s connected world. If your marketing department doesn’t have a subscription to an SEO tool like Ahrefs or Moz and lacks a digital marketing strategy, its time for a change.

47. Understand product market fit.

You may think you have the best product in the world, but it doesn’t matter if it isn’t what people are looking for. Once, I spent a bunch of my own money and investor money to develop what I thought would be a great product. It flopped because nobody was looking for that particular solution. Try to not spend a bunch of money on a flop.

When a customer pays money for something that’s when you know you have something. The gap between“wow, that’s pretty cool” to “here’s my money!” is not a gap, it’s a chasm. Customer money is the best way to build anything and ultimately is the only way to build something lasting.

Editor’s note: if you are an entrepreneur, this concept is the most important thing in this article yet strangely difficult to put into practice.

48. Understand how skills in your current industry could apply to another.

Transition learning, or the application of skills in one industry to another, maximizes learning intake. Elon Musk talks about learning as a semantic tree and to establish fundamental principles, i.e. the trunk and big branches before you get to the leaves/details or there is nothing to hang them on.

Certain business elements transfer across industries. Case in point, let’s take Jennifer who recently switched from being an aerospace engineer at Boeing to doing structural engineering at Baker Hughes.

If Jennifer thinks of Baker Hughes as being a TOTALLY different industry with a bunch of unfamiliar API and ASME codes, she has framed the challenge in a limiting way. Jennifer’s focus on the branches prevents her from building on her previous knowledge.

But if she looks at Baker Hughes as being an entity inside of a capitalistic ecosystem whose behavior is governed by stakeholders and whose product is subject to regulatory standards like her old employer, she’s starting with the trunk. And chances are building out the branches and leaves will be far easier.

49. Understand privately owned companies and their motivations.

Privately owned companies tend to have a high variability in financial performance and their treatment of employees. I’ve worked for a private company that removed the doors from the restroom stalls to “prevent employees from milking the clock.” My buddy’s boss saw his internal struggle over his budgeting stretching decision to buy a new house. When he came back from lunch there a $10,000 check on his desk and a sticky note. “Buy the house.”

A private’s owner’s motivation varies wildly when compared to the monetary aims of a private equity-backed or public company. A private owner may have no real concern about making money. He might be motivated by a vendetta against a former employee who started her own competitive firm. Work for a private company and you can believe one thing: It’s going to be a little odd.

50. Understand private equity backed companies and their motivations.

Private equity backed companies exist because they believe they can buy an undervalued or underperforming assset and create significantly greater value for their stakeholders. Does it work? Sometimes. One of the challenges of working with a private equity backed company is many of the decision makers lack operating expertise and bring a completely financial focus to a business operation. The best private equity firms see this as a potential shortcoming and pair the bean counters with deep operational expertise. The worse tend to oversimply the value that strong operators bring to the business by continually cutting expenses and personnel to be profitable.

51. Understand public companies and their motivations.

Public companies operate from their stakeholder incentives. And the vast majority of the time, a publicly traded company is incentivized to produce maximum value for their shareholders. Specifically, this means a focus, and often a fixation on quarterly results. Companies report financial results on a quarterly basis, thus driving employees to “bring in as much revenue” at the end of quarter. As a project manager, this routinely caused me to incur extra costs for no other reason but to satisfy the very stakeholders who needed me to maximize the project’s profit.

Strong companies with good leadership can sometimes shake this barrier. Apple is a good example of a company that routinely overperforms expectations to the point where analysts realize their projections are sandbagged. A company that prints cash like Apple has this kind of flexibility. Most don’t.

The benefits of a publicly-traded company usually include world-class training and support. Highly trained and talented engineering personnel are usually available to support new and struggling engineers. Whereas smaller companies are at the mercy of Google and any free resource they can scourge up.

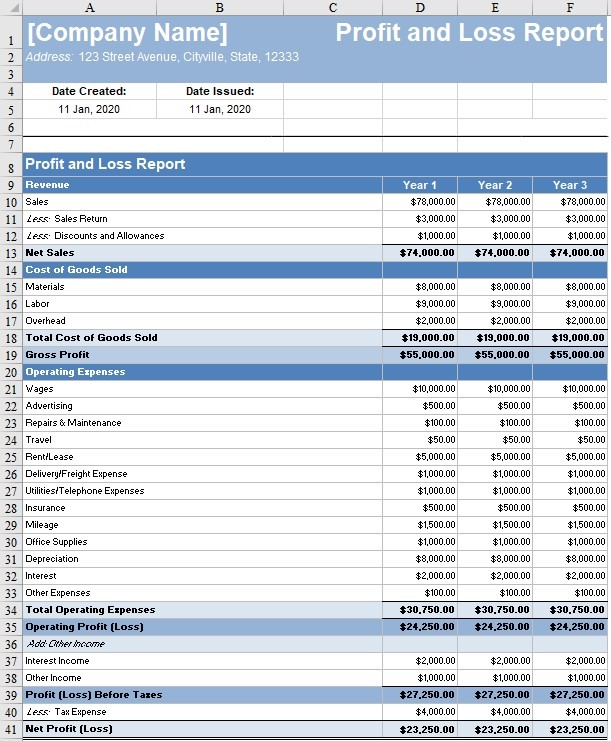

52. Understand a P&L.

Being able to read a P&L is crucial to understanding the state of a business whether you care to be involved in the business side of that company or not. Let’s say you are evaluating two offers: Triton Pumps and Bison Centrifugal. Both are publicly traded companies. Salaries, culture, and all other factors are effectively the same. So what’s the tiebreaker?

Go straight to the P&L. Understanding their cash position, how they spend money, and where they are placing their reserves will help you make an informed decision on what type of behavior you can expect from that company. Public companies file their P&Ls as part of a publicly available 10-K. The finances of private and public equity backed companies are usually tougher to obtain. But there’s harm in saying, “Do you share financial performance data?” when an offer is being evaluated.

53. Understand project margin.

Just as companies are run on a P&L, projects are run on margin. Gross margin percentage, typically referred to as margin, is the percentage difference between the sell price and the profit. Margin is frequently confused with markup. Markup is the difference between the selling price and cost expressed as a percentage over the cost. Markups are always higher than their corresponding margins.

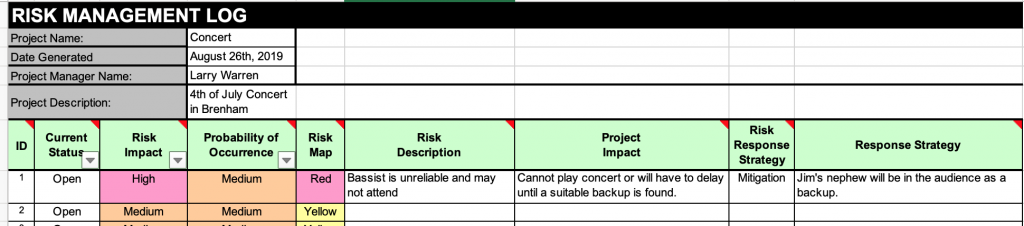

54. Understand project risk and its impact on project evaluation.

For a project-based endeavor, a proper understanding of risk, risk assignment, and risk mitigation is crucial. In customer-supplier relationships, the risk is typically pushed down the value chain to maximize the possibility of financial success for the asset holders.

Fortunately, risk can be quantified through a careful examination of project requirements and the nature of the project being executed. A project being executed in a foreign land has an entirely different risk profile than one built stateside. Complexity generally increases as the price tag increases, for projects that have a novel process, and when multiple stakeholders are involved. Being able to quantify these elements and apply a risk profile helps an organization determine how to resource a project and what contingency matters to put in place. There are tools that integrate into scheduling software, but often, a simple log is just as effective.

55. Microsoft Excel is simultaneously the most overrated and underrated tool you will use.

Like many professionals, I use Excel for pivot tables, sorting, and general reporting. It can perform a litany of other functions from automating a process via macros or serving as an ad-hoc calculator. A few problems with Excel:

- Creating anything in Excel has become a knee jerk response to perform reporting and data manipulation in Excel that’s best left to an enterprise platform.

- There are way too many logs floating around of useless information. After seeing a problem that a manager doesn’t feel comfortable on acting upon, he tells an employee to rectify a problem by saying “Let’s log this information and then take actions on our findings.” That employee faithfully documents problem after problem in the log and the manager never takes any action.

Pivoting data and analysis of findings are functions where Excel thrives. Yet too infrequently Excel is misused as a data collection tool and substitute accounting platform.

56. Understand the cost of production methods.

Each individual step of production adds additional cost. Understanding how much machining time, operations, welding, testing, shipping, and additional finishing steps costs allows for true cost evaluation. Too often, economic analysis doesn’t include post-processing or take fully into account the time humans spend supporting the product.

57. Understand the return on investment (ROI)

From an academic perspective, there are several different ways to quantify ROI.

- Dividing net income, interest, and taxes by total liabilities to measure rate of earnings of total capital employed.

- Dividing net income and income taxes by proprietary equity and fixed liabilities to produce a rate of earnings on invested capital.

- Dividing net income by total capital plus reserves to calculate the rate of earnings on proprietary equity and stock equity.

Informally, most companies think of return in investment in months. For instance, if $15,000 is deployed on a project, the ROI is 15 months if that deployed asset returns a profit of $3,000 a month. This time horizon becomes especially important depending on the type of company you are working for. If they have a short-term capitalization strategy – i.e. a private equity firm that wants to sell in a year, ROI projections must be very aggressive whereas in other scenarios a payback period of three years or more may be just fine.

58. Understand burden rate.

“Wow they are paying that guy $30 an hour and billing him at $75. What a racket!” This kind of statement surfaces frequently and shows a lack of business acumen. Let’s do some quick back of the envelope math:

A welder gets paid $30/hour x 1.15% of his wages for taxes and benefits + cost of the building + cost of electricity + time lost to the training.

Suddenly that $75/hour bill rate doesn’t look so high. One of the key factors that determines the profitability of service or manufacturing company is utilization rate.

59. Understand utilization rate.

Employees who bill time typically categorize this time into “non-productive” and “productive” frequently. No, “non-productive” doesn’t mean that an engineer is watching television. It is simply cost that cannot be passed onto the client. This could be training, internal tool development, and depending on the calculation method, vacation time. Utilization rates give companies a good indication of overall business health and typically are set around 80%.

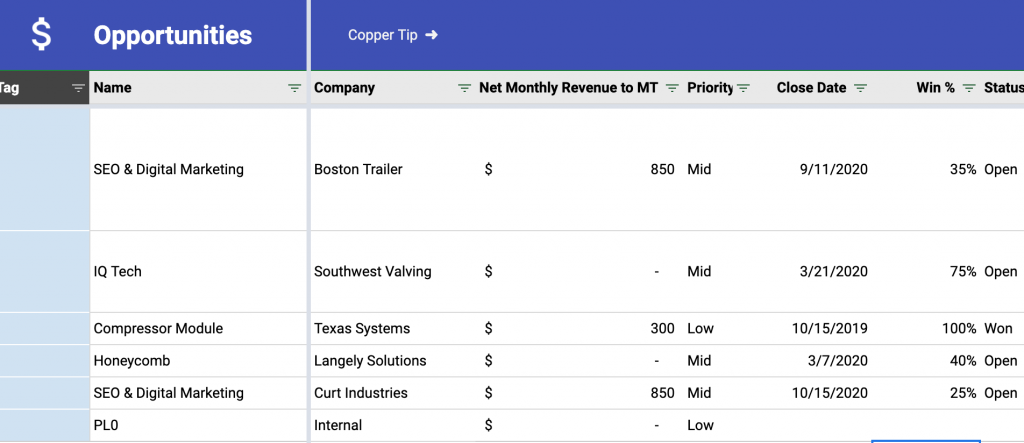

60. Understand the value of customer relationship management system (CRMs).

CRMs store customer data and allow actions to be tracked against those actions. CRMs are typically owned, monitored, and updated by the sales team. However, they are also particularly useful in a manufacturing environment to allow technical talent to plan projected work and anticipated resources.

61. Understand enterprise resource planning systems (ERPs).

Enterprise resource planning systems are the brain of any significantly sized organization (typically revenues at $10 million or greater). How that ERP system is structured has significant impacts on day to day activities of an engineer. At a minimum, an engineer needs to know how the bill of material (BOM) is entered. But many times, the engineer will be entering material, releasing the BOM in the system, providing status updates, and ensuring the right material and disciplines are in place to produce a strong piece of equipment.

AN EFFICIENT AND EFFECTIVE ENGINEER

Being an efficient and effective engineer means getting more with the same amount. In the interest of efficiency, let’s get right into it.

62. “Should I get a PE?” There are few questions that are more situational.

I waffled on whether to get my PE or not many times. I bought the book, studied, and other career priorities snuck ahead of it. I actually still desire a P.E., but its buried so far down the list of priorities it likely won’t see the light of day until the retirement home.

If you are civil engineer and do any kind of technical work, getting the P.E. is a no-brainer. For mechanical engineers, the choice is more difficult and typically not directly applicable to the work at hand. Some Engineering Manager job descriptions require a P.E. and often for prestige and perception reasons only. So, should you get one? Evaluate the opportunity cost by comparing the time and expected ROI to all the other cool ideas running around in your head.

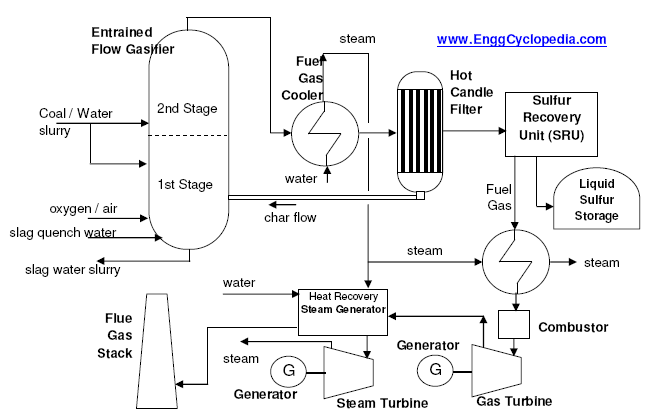

63. Understand process flow development.

The first step in any processing operation is to generate a mass flow balance and a process flow diagram. This is typically done with the aid of a software processing solution such as Ansys. The software processing solution produces a material balance that ensures material conservation principles are accounted for during the process. The process flow diagram (PFD) is a high-level depiction of how inputs are taken into a system, ran through various process operations and returns, and an output is generated. The PFD serves as the basis for the piping and instrumentation diagram (P&ID), equipment datasheets, and the subsequent design of a processing system.

64. Understand the piping and instrumentation diagram (P&ID) development process.

P&IDs are the single quickest way to understand what is happening in an industrial process. The P&ID shows operating conditions, major equipment, valves, and instrumentation required to run, monitor, and control a specific process. It is typically the first major deliverable for an equipment provider and provides the system design for all subsequent documents.

Development of a P&ID is typically a team effort, spearheaded by an engineer. The engineer drafts the P&ID himself or employs a drafter. Other speciality engineers and the project manager typically give input on needed requirements.

65. Do a P&ID walkdown.

The P&ID becomes a lot more real when you do a walkdown. A walkdown is following the P&ID against the equipment that has been built and marking up any discrepancies. Walking down a piece of equipment and seeing how the engineer’s design affected the final build is exciting. Or disappointing, depending on how well the P&ID was put together.

66. Know ASME code.

Knowing the general specifics of which code applies and when is a big start. For those with a peculiar – er -particular passionate for understanding the codes, you could spend a bunch of time digging through thick ASME books. Your time is likely best served by concentrating on what the ASME Boiler and Pressure vessel code says about a few important issues: code applicability, joint efficiency, hydrotesting, design pressures and temperatures, and testing requirements. Section VIII is the most universally applicable section of the ASME Boiler and Pressure Vessel code.

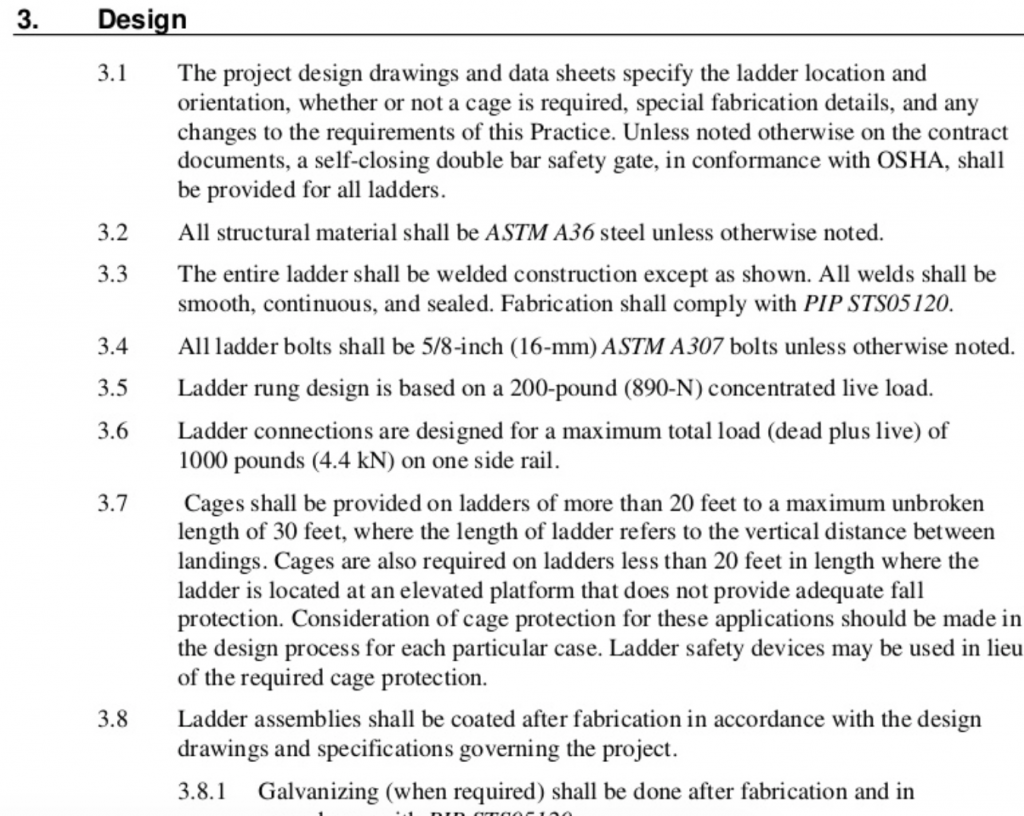

67. Read a project specification and mark it up.

Operators or EPCs, when obtaining a bid for a project, supply equipment providers/integrators with a detailed list of specifications. These specifications tell the end-user how the equipment should be built. Specifications typically are per discipline as there may be a piping specification, a structural specification, and a vessel specification. Specifications may also get a lot more granular – down to how a nameplate should be affixed.

An equipment provider must review the specification in detail and mark up the specification to correspond with the bid being provided. Sometimes the specified material or approach suggested by the client is unnecessarily costly. Sometimes the equipment provider may lack the expertise or capability to perform to the required specification. It’s essential that any variances are noted prior to the submittal of a firm bid and that those variances are clearly noted.

68. Go to the Shop.

As a newly minted engineer, the shop intimidated me. Here were these gruff guys who picked up a welding torch before my life started and I’m supposed to supply work guidance? AWKWARD. But like most life experiences, actually doing it made me realize there was nothing to fear. Resist the temptation to sit in the office. Get out there, be awkward, make some friendships, and appreciate the great and underappreciated craft of joining metal.

69. Work in the shop if possible.

It’s great to go to the shop. It’s even better to work in the shop. I spent the first three weeks as a new motor engineer working alongside the assemblers putting together windings. The experience not only gave me a great appreciation for the work, but the workers as well.

It’s one thing for an engineer to know that “drilling through stainless is difficult.” Its quite another for that engineer to drill through stainless. The difficulty won’t be forgotten when specifying work methods and materials.

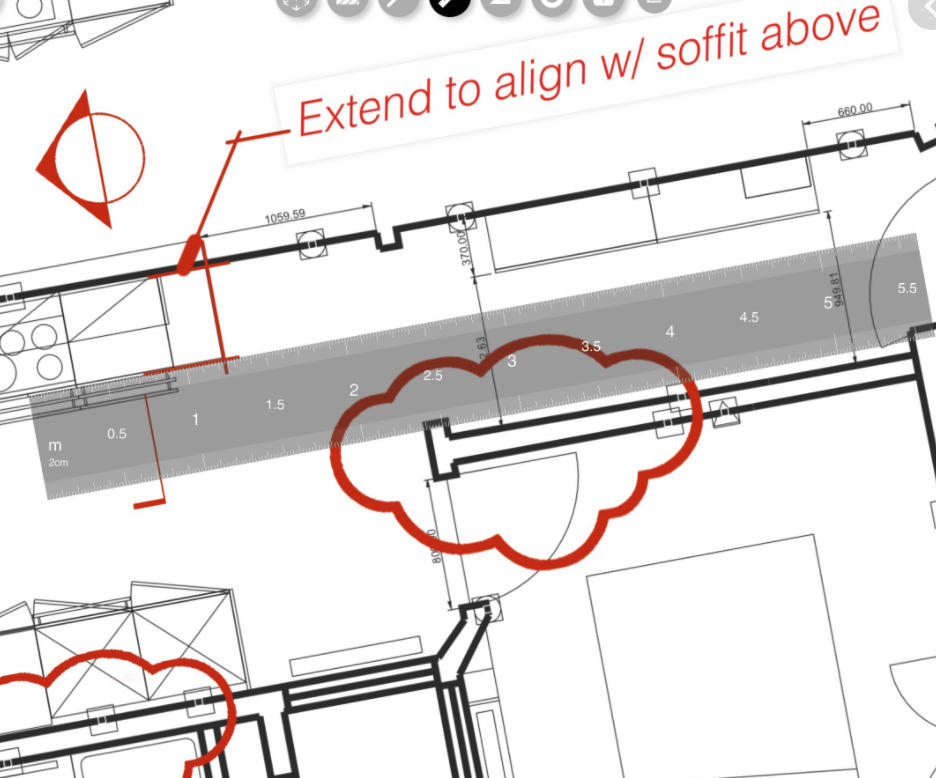

70. Redline appropriately.

The redline of drawings is a useful tool that allows quick changes to be made to an issued drawing that resides on the shop floor. Most facilities authorize redlines when it does not affect the form, fit, or function of a particular component or assembly.

In some facilities, only the engineering team is allowed to make redlines while in other manufacturing operations all workers may perform redlines. Redline authority should be established on a product line and facility basis. A new revision of a drawing should always be generated from drawing if the redline becomes too extensive or lacks legibility.

71. Be part of a hazard and operability study (HAZ-OP).

If I was an engineering student or new graduate, an early ask of mine would be to sit in on a HAZOP. The HAZOP process kicks the tires of a P&ID to make sure the plant or process operates safely under any conditions. Most HAZOPs are single or multi-day systemic granular looks into the operating of the equipment and usually involve the equipment provider, customer, and a third-party engineering firm.

72. Get really good at a niche skill.

There’s a lot of value in being deeply talented at a particular skill. Let’s say you are “the foremost technical expert on plug and perf operation”. Most non-technical personnel don’t really understand what you do. Thus, a layer of career durability is built-in that cannot be matched by the business guys. At one of my jobs, a subject matter expert on oil processing used to wander off for 2-3 hours every day. I don’t recommend this as a career strategy, but the managers let him do that because his knowledge was revered and objectively irreplaceable. Thus, he effectively determined when and how he was going to work.

To be get really good at niche skill means you probably studied engineering because you were a tinker and liked to see how things worked. I tried the technical route myself early in my career, but soon realized I had no interest in winnowing my knowledge to a small realm of expertise. If your DNA rebels against smaller and smaller scopes of work, then…

73. Become a jack of all trades.

Becoming a jack of all trades doesn’t mean a superficial career path – it’s an intentional one. It’s understanding the deep and hidden connections between trades and industries that are seemingly disconnected. It’s understanding the fundamentals of various technical disciplines and trades. It’s insurance in an economy that moves so quickly that the specialist can often be left behind.

74. Understand different control schema.

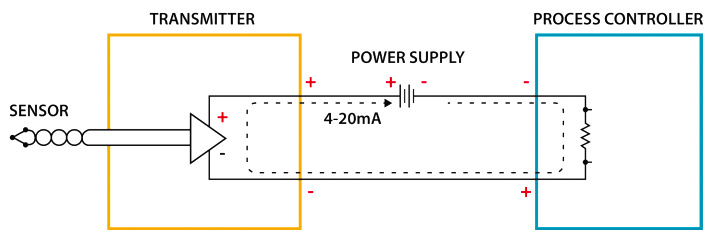

A strong instrumentation system takes multiple inputs and allows automation of process where feasible. Many systems require manual operator control. There is no “right” or “better” answer. It simply depends on the needs of the business operations. Know the difference between local and system control as well as 4-20mA and Fieldbus system controls. Understand how instrumentation is represented on a P&ID as well as a cause and effect diagram.

75. The answers are not always binary.

The engineering process is great for decision making and a providing a decision-making construct. But what happens when you don’t have enough data and the decision can’t be easily modeled? This is where understanding and sensitivity to commercial issues comse into play.

Years ago, I shipped a unit that had repeated vibration issues. It was a $1.2 million reciprocating pump package. Due to a variety of factors, isolating the source of the vibration was extremely difficult, even for our outsourced vibrational experts. We never did find a binary answer to the source of excessive vibration. Nonetheless, the customer left satisfied with our mitigation attempts to meet their nebulous “user comfort” requirements. How? Intentional discussion with our team, pump vendors, and the customer that prompted a team-based approach and significant dampening of the vibration issue.

76. Its ok to play a little dumb.

One of the best tactics when you are new to a situation is simply to ask questions. Even better, ask the same question to multiple folks. “How good is our time delivery?” is an example of something you might ask several different people in various functional areas. That question will give you context not only into the actual on-time delivery performance but into the perception of the on-time delivery. This insight into the perception of the on-time delivery tells you what sales really thinks about the engineering team or shop. Connect those dots to better understand personnel dynamics.

77. But don’t play too dumb.

I worked three years for an equipment provider, two years at a consumer startup, then took a job at an equipment integrator. When I stepped foot into the equipment integrator, I had never even looked at a P&ID in my life. It was my first day on the new job and this new term “P&ID” was getting bantered around the water cooler. By the mentioned context it was clear that “P&ID” was a need to know, not a nice to know term. My gut told me to be quiet and google it later.

Some months later, I realized keeping my mouth shut was a good call. A P&ID is such a common practice of equipment integrator, it would have caused the old veterans to question my hiring.

78. Learn basic equipment.

There’s perhaps no single way to leapfrog your peers and turbocharge your career than to understand the mechanical details of what you are building. Read about what essential equipment does and how that equipment is specified and verified. Whether your industry is oil and gas, wastewater, or nuclear, the fundamentals of equipment design and production remain the same.

79. Run some electrical.

Running electrical and knowing how much extra wire should be accounted for makes the process of specifying it much more real. When specifying wires, the impact of under-sizing landing terminations will be much more real. You will gain a new respect for electricians, the types of raceways, and code applicability.

ENERGY INDUSTRY

Whether you are drilling for oil or building a robot vacuum cleaner, knowing the nuances of the energy industry provides great insight into how projects are manufactured and brought to reality.

80. Understand the phases of equipment project engineering.

Project engineering is a short-term endeavor that involves the design of a product to achieve a particular aim. Most challenging and large scale work involves project engineering.

The project engineering phase can be further broken into five discrete and overlapping stages. The initial stage is process engineering although sometimes an equipment supplier may not have process capabilities and only takes project engineering into their scope. Project engineering is followed by discipline-specific engineering. The design stage is when the equipment is laid out, usually in a 3D modeling program. This is followed by detailed drawings, a straightforward process with little creative or subjective interpretation.

81. Understand industry acronyms.

“Make sure that WPS on the TIG and its application is in line with the G/A and NDE certs are complete so we can get ready for the FAT and the SAT.”

Whaaaaaaaat?

Here’s a highly incomplete list of acronyms that you will run across when engineering equipment. What are we missing!? Let us know!

82. Understand Non-Destructive Examination (NDE).

NDE, sometimes referred to as non-destructive testing (NDT), is how the integrity of mechanical work performed to a piece of equipment or component is verified. Most often in a fabrication environment, this pertains to NDE examination of welds. Understanding and knowing when to use the most appropriate kind of NDE helps you plan the project’s cost as well as execution dynamics.

83. Check on Verify the work progress of vendors

Ronald Reagan famously and routinely said during the Cold War, “Trust, but verify.” While building a strong bridge of trust and compassion for subcontractors is important, verifying that work is completed to schedule is essential.

I was managing a project for an equipment provider and submitted a schedule to Craig, who represented the EPC and thus the operator’s interests. Craig shook his head and frowned. “There’s no way you are 63% complete. Based on what I’m seeing out there it’s more like 50%”. I argued. We went back and forth for days. After the scheduler found an error and re-ran calculations, it was clear we were approximately 52% complete.

Work verification is an active process whereas checking simply takes the vendor’s comments at face value. Sometimes checking is fine – there’s no need to require slews of documentation for simple orders. But when verification is required, understand how to validate information that you is being supplied.

84. Scheduling is an art form.

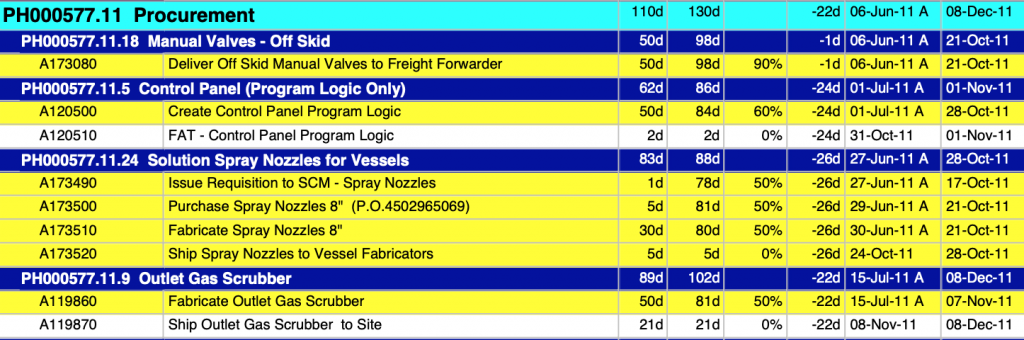

At times, you might be fooled that scheduling is a science by graphs like these.

Yes, all of that’s true, but whoever owns the scheduling role in an organization must understand how works flow and where the weak points are is worth his weight in goal.

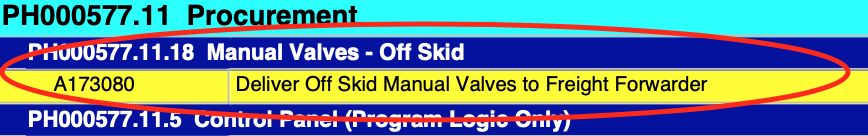

See this task?

Probably not a lot of risk baked in.

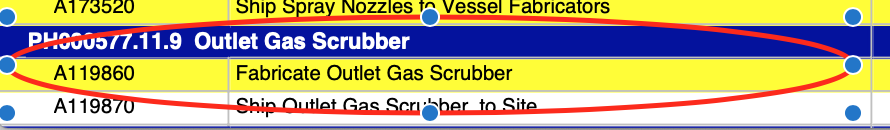

Now see this task?

Always a lot of risk baked in.

Knowing customer tendencies, internal staff dispositions, and weak points in the supply chain is the key task of whoever owns the project schedule. As an engineer, if you understand these nuances, you can better plan for disruptions and weak points in the project schedule.

85. Understand a designer’s world.

Yes, modeling is a piece of being a strong designer, but a small piece. A strong designer not only has to model effectively, but interact seamlessly with ever changing engineering data, interface with the shop, and understand client requirements and regulatory standards. The best designers are attuned to fabrication concerns and have a control over the BOM. One of my favorite designers of all time bought the shop cookies when he screwed up. I miss that guy.

86. Understand quality and its various branches.

Quality is typically a single functional department, comprised of two functional areas: Quality Assurance and Quality Control. Quality Assurance is quality applied to a build process to ensure the methods are correct and optimized. Quality Control ensures the resulting goods of a process meet required criteria and are suitable for use. Quality Control implements processes and protocols to measure the quality of the produced good. These may be, but are not limited to: Non-Conformance Reports (NCRs), Correction Action Required (CARs), and any other reports that pertain to the disposition of a product.

And the quality department should never, ever, report to production.

87. Expediting is an art form.

Expediting can either be a dedicated job role or a function shared by multiple personnel. With that being said, I can’t count the number of times a stuffed shirt roared at me to expedite something really stupid. If you have a customer yelling about the delivery of 1” ball valves and there are five huge quick opening enclosures being manufactured in Italy on the critical path take a deep breath and find your inner Joe Montana.

Regardless of whether the expediting function is a dedicated job role or a distributed responsibility, all engineers must expedite at some point. This may be done via formal delivery agreements or requesting a supplier to improve deliveries. And sometimes it’s not even worth putting on pressure for a delivery…like those 1” ball valves.

88. Be part of a factory acceptance test (FAT).

The FAT is a regimented, typically multi-day testing of equipment to ensure it performs as expected. Hanging around a FAT is a fascinating insight into how an equipment provider ensures proper provision of their equipment and handles client concerns.

An equipment provider should typically have a Pre-FAT to ensure most, if not all of the function errors are worked out. Unfortunately, that doesn’t always happen. The best equipment providers not only perform a Pre-FAT but are pro-active about planning the FAT, establishing a punch list, and ensuring issues are rectified as assigned and promised.

89. Freight is not to be treated lightly.

I had a few sleepless nights when a major project of mine was stuck on the border of Michigan awaiting permits. Once, I screwed up on getting the proper insurance papers for a barge shipment. Not cool. Freight is an easy thing to mismanage because the responsibilities are different on nearly every project. Study Incoterms, keep freight costs flexible, get permits way early, quality component freight costs, and properly plan for mega-transport jobs are all big lessons I learned the hard way.

90. Know the up, mid, and downstream segments of the oil and gas market.

If someone says they are in the upstream market, they are primarily concerned with taking petroleum out of the ground. Midstream deals with transport of the oil and gas, whereas downstream deals primarily with processing and refining of the oil or other process media.

As a result, the characteristics of each market segment are significantly different. The upstream market experiences the greatest demand fluctuation as exploration and drilling activity is directly tied to supply and demand economics. Midstream also relies heavily on supply and demand economics but can adjust to market economics by reversing the course of supply. For instance, when domestic LNG supply skyrocketed, many import terminals were converted to export terminals. Downstream is more isolated from swings in production than its upstream and midstream brethren as the processing of liquids and gases reaches outside of the oil and gas supply chain. An equipment provider in the downstream arena that makes and markets downstream processing equipment typically has a foothold in other industries. For instance, downstream projects include wind generators, remote battery rooms, landfill gas clean-up, even marijuana e-houses.

91. Understand the energy value chain.

The energy value chain used to mean strictly “petroleum-based reserves value chain.” Much has changed in the last few decades, as alternative energies such as wind and solar have shifted the landscape. Nonetheless, every product that is being extracted, refined or created has a structured group of companies that work together to capitalize the asset. The shot caller is typically the operator, who either owns the asset that is being created or developed or has partnered with the asset owner to provide technical services for asset development. Next on the chain is an engineering procurement construction (EPC) company that is responsible for the engineering, procurement, and construction of an asset. The EPC typically does not actually build anything, but project manages and ensures technical compliance of the build. Equipment integrators bring a multiple of components from valves to instruments, pipes, and equipment into a single or multitude of packages. The equipment provider may work with an EPC company or directly with the asset owner. Supporting the equipment integrators are the various equipment and component manufacturers and distributors.

92. Work for an operator.

Operators own an asset that is being developed or have a commercial arrangement in place with the owner of that asset. In the evaluation of conventional energy producers, examples of operators are Shell, Exxon, or British Petroleum. There are also a litany of operators that develop smaller assets or optimize existing assets. Operators strategically outsource detailed engineering, equipment building, and equipment purchasing to contractors.

93. Work for an engineering, procurement, and construction (EPC) company.

There’s engineering purity in working for an engineering, procurement, and construction company. Most of an engineer’s time in these organizations directly applies to a project or proposal. As such, the pressures to stay billable is immense. When the economy contracts or booms, EPC companies go on drastic hiring or layoff sprees accordingly.

EPC companies typically work for an operator and directly with an equipment provider. As the complexity of a project increases, the likelihood of EPC involvement also increases. To keep up with the challenging energy market, EPCs in recent years have reduced domestic staff and place much more of their engineering talent in lower wage offshore markets. While cost reductions have been realized, communication gaps and tensions between home offices and international counterparts have resulted.

94. Work for an equipment or component manufacturer/distributor.