Process filters clean liquid and gas to meet purity requirements in industrial applications. Required filtering considers the contaminants to be removed and often occurs in tandem with knock-out drums, electric heating, centrifuges, and heat exchangers. These specially designed filters remove entrained sediments from a media stream. In this article, you will learn about filter specifications, filter types, and maintenance considerations.

Specifying A Filter

Specification of an appropriate filter involves contaminant removal requirements, the throughput volume of process media, and operating conditions of the process media.

While filtration can be an inline process of simply putting a media filter in front of a process stream, most processes require a more intentional approach. This may involve the creation of a pressure vessel to provide a filter housing, the insertion of knock-out drum to remove large particles, an electrostatic precipitator, or an electric heater or heat exchanger to raise the dewpoint.

Most gas-fired systems require dry and oil-free gas. Process filter designs accommodate these specifications. Maximum allowable differential pressure sets the final size of a filtration system to ensure gas face velocity does not generate too much too noise.

Filter Types

It is useful to group filters according to their general design: bag filters which aggregate particles internally, cartridge filters which generally collect debris externally, and media filters.

Cartridge Filters

Cartridge filters remove solid particles that may cause damage to the product’s operating system. Debris can collect on the surface or through the entire thickness of the filter. Specification of cartridge filters typically occurs in two parts: the housing which holds the cartridge in place and the replaceable cartridge.

The cartridge housing is typically made of stainless steel or carbon steel. Filter cartridges usually comprise of thin materials like papers, woven wire, and cloth. These filters typically require routine disposal and replacement but may have a cleaning system for difficult to access applications.

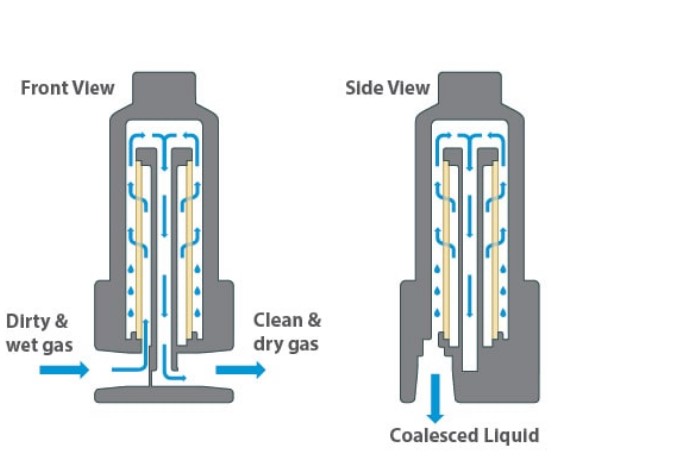

A special type of process filter called a coalescing filter aggregates small liquid aerosols until they become bigger droplets. Once droplets grow to a certain size, they drain away gravitationally. Coalescing filters are common in gas applications where pre-ignition moisture removal is crucial.

Bag Filters

Bag filters purified gas or liquids. Dust-laden gas or liquid enters the filter and dust cake/sediment collects in the bags. Typical material of construction is felt and nylon mesh. Bag filters provide low operating cost and good applicability to small batch operations.

Bag filters produce less solid waste than cartridge filters which makes them a strong choice for applications where minimization of solid waste is important. Filters generally do not require replacement upon clogging. Rather, their design allows for cleaning via mechanical shaking or backwashing. Common industrial applications for bag filters are for coolants, cleaning fluids, and chemical purification.

Media Filters

Media filters use glass, carbon, sand, biomaterial, or other specially designed products to remove impurities from a fluid. The filter media may be either unactivated (no pre-processing treatment) or activated. Filter activation occurs thermally or chemically. The activation process optimizes process media to filter media contact. Thermal activation increases the temperature to create steam, opening the pores of the filter media. Chemical activation uses a strong base, acid, or salt in conjunction with heat to initiate activation.

The main principle behind this filtration process is that of ‘adsorption’. The porous structure of carbon granules traps fluid contanminants. Removal capabilities and operating properties depend on the filter media type, the type and amount of pollution present, process media acidity and temperature, and contact duration.

A very common type of activated filter material is carbon. Carbon provides a great deal of porosity, is commonly available, and is effective for a broad range of materials. Common applications of activated carbon filters are water purification, air purification, and industrial gas processing.

Maintenance Considerations

Maintenance considerations depend on the type of filter used and the manufacturer’s recommendations. All filters are cleaned or replaced on a routine basis. Some operators replace filters on routine time intervals, but a more economical method is to monitor the pressure drop across the filter. When the filter pressure drop reaches a certain amount the filter should be cleaned or replaced.

The process of cleaning may involve mechanical shaking or backwashing. Mechanical shaking of bag filters removes accumulated contaminants. Backwashing provides another method of cleaning a filter. In the backwash process, a differential pressure applies across the bed and then washes in a backward manner. Thus, the flow of the water is opposite to the normal flow.