Pipe flanges connect pipes, valves, pumps, and other equipment to form a piping system. They also allow for a modular build of equipment in a shop environment. During operation, the pipe flange provides easy access for cleaning, inspection, or modification.

In this article, you will learn about common flange materials, flange face types, pipe flange types, and dimensions.

Common Flange Materials

As a standard, flanges, composed of stainless steel (316SS or 304SS) or carbon steel. Materials outside of these are considers exotic and specified due to process media requirements.

Flange Face Types

Flanges have three different mating faces – flat face, raised face, and groove face.

Flat face flanges have bolting and pressure retaining faces in the same plane. Flat face flanges are the most economical flange type and are used for non-critical, low, or no specification piping.

Raised face flanges isolate the pressure retaining connection from the bolting connection. Raised face flanges are intermediate-price and are the most common type of flange used in process equipment.

Lastly, the ring-type joint flange commonly refers to as RTJ flange, suits high-pressure, critical applications. The softer gasket material that seats in the groove area compresses against the harder metal material making an extremely efficient seal.

Pipe Flange Types

Flanges come in seven different types of connection configurations.

Slip-on

Slip-on pipe flanges slide over the line. Their machined inside diameter measures slightly larger than the outside diameter of the pipe. This allows the flange to slide over the pipeline yet provides a somewhat snug fit. Also, slip-on flanges secure to the pipeline with a fillet weld at the top and the bottom of the flange.

Socket Weld

Socket-weld flanges attach by inserting the pipeline into the socket and applying a weld around the top. Socket weld flanges are typically utilized on small pipeline sizes.

Weld Neck

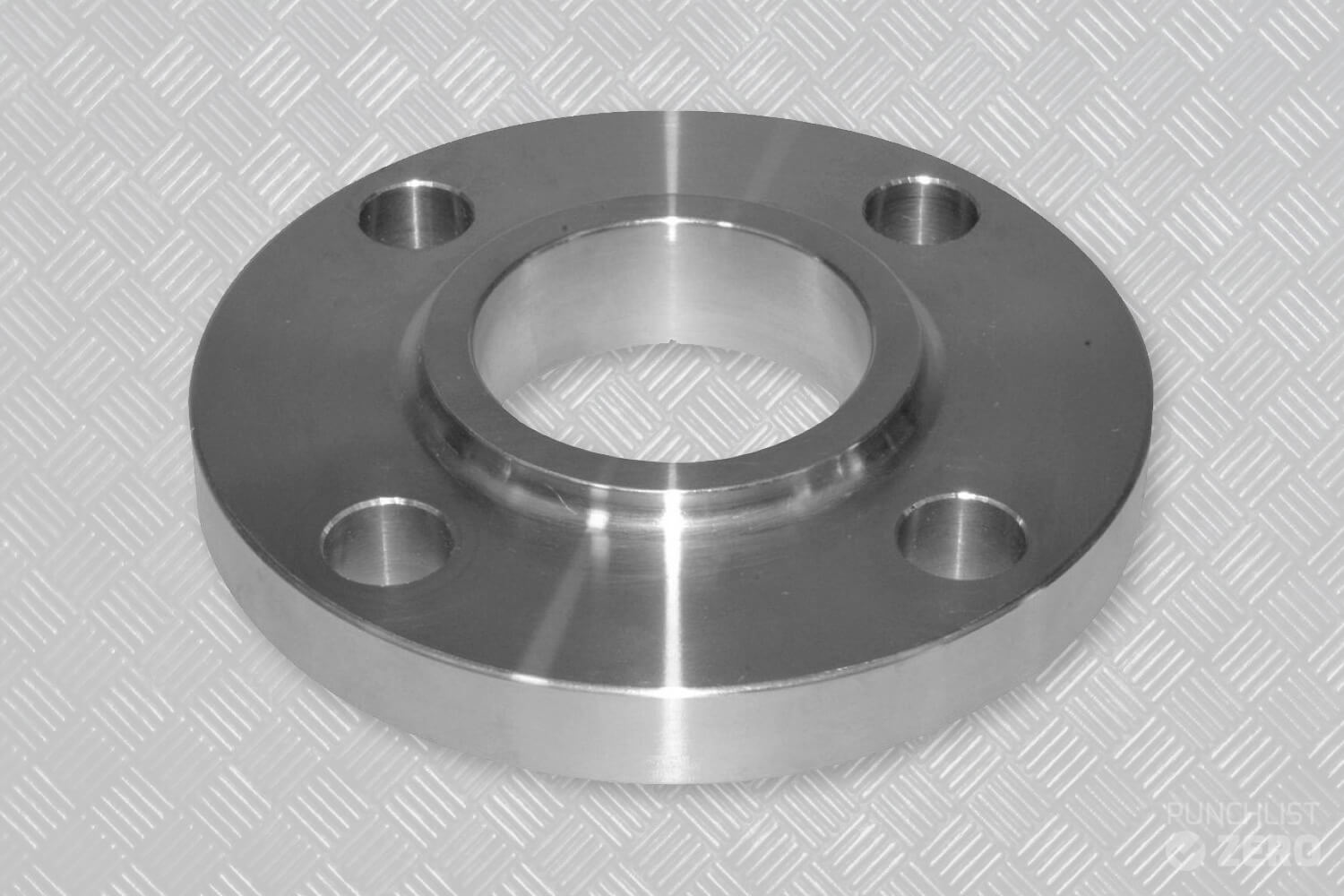

Installing the weld neck pipe flanges includes welding the pipeline to the flange neck. This allows for the gradual stress transfer from the flange to the pipeline. It also reduces high-stress concentration at the base of the hub. Weld necks find common use in high-pressure applications.

Long Weld Neck

Long weld neck flanges appear similar to weld neck flanges with a longer pipeline neck. However, the longer neck eliminates the need for an individual pipe piece in many cases.

Long Weld neck flanges typically cost more than regular weld neck flanges and also require long lead times. However, they are known to be highly reliable and reduce fabrication efforts as compared to the normal pipeline to flange type nozzles.

Threaded

Threaded flanges provide a design similar to slip-on pipe flanges with a threaded bore. These flanges screw onto threaded pipe without welding. While somewhat rare, engineers sometimes specify these flanges for small diameter, high-pressure requirements. These flanges may utilize thread sealant to ensure a durable connection.

Lap Joint

Lap joint pipe flanges fit over a pipeline and commonly pair with stub ends. Pipe typically welds to the stub end and the lap joint freely rotates around the stub end. Lap joint flanges suit applications that require frequent dismantling.

Blind

Blind flanges bolt directly to the end of a pipeline or pressure vessel openings to prevent flow. This can be particularly useful to isolate a pipe or pressure vessel for hydro or pneumatic testing. Thus, blind flanges can be used in lieu of t-bolt or quick opening enclosures to allow easy access and are frequently seen in high-pressure applications.

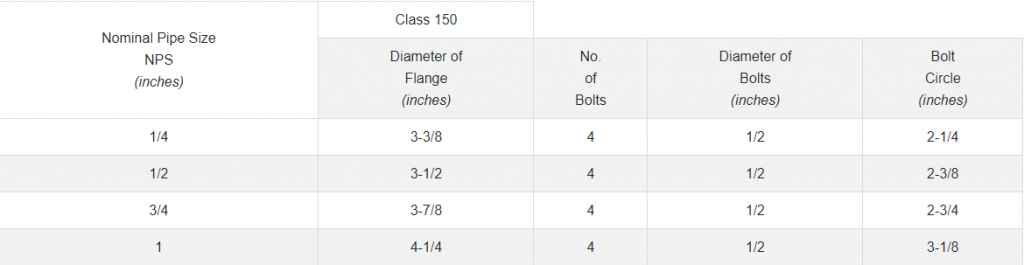

Pipe Flange Dimensions

The size and thickness of pipe flanges vary based on two paremeters: temperature and flow pressure. The most typical pipe flange for ½-inch lines has an outer diameter of 2.83 inches. In addition, the pipeline size and pressure class required for the application define the flange dimensions. Publications from organizations like ASME, MSS, API, provide standard flange sizes. Pipe flange dimensions usually range from 1/2″ to 24″ in diameter, with classes ranging from 150 to 2500. Note that the ratings are per ASME class xxx or API xxxx terms.